- Joined

- Aug 25, 2018

- Messages

- 53

- Points

- 10

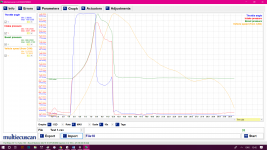

This is the first turbo car I’ve owned so not entirely confident in dealing with issues that may crop up, but I’ve noticed that my car is making a loud whooshing noise under load and then off throttle the recirculating valve sounds more like a dump valve if you know what I mean; it was all a comparatively silent operation when I first got the car only a few weeks ago.

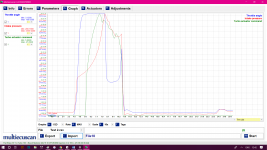

Also last night coming home from work I noticed a very obvious flatlining in power at around 3k rpm which the car doesn’t recover from. This was at full load and was what made me determine it’s a boost leak, I have since continued to drive but taking it very easy.

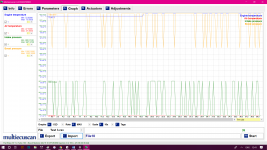

I had the car jacked up this morning and inspected all the boost pipes; nothing abvious in terms of leaks using a handheld sprayer with soapy water on them. The solid inter cooler pipes are corroded but not leaking. I unplugged the recirculating valve and drove around and still the same.

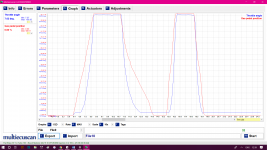

Is it worth noting that I could not replicate the noise while the car was jacked up on axle stands? Revving the engine full throttle jacked up it sounds normal, only once I’m out on the road does the noise return

It’s hard to determine exactly where the source of the whooshing is coming from when inside the car driving along, but it does sound like it’s up top in the engine bay and not low down, can the PCV valve have anything to do with this?

Your feedback is appreciated

Also last night coming home from work I noticed a very obvious flatlining in power at around 3k rpm which the car doesn’t recover from. This was at full load and was what made me determine it’s a boost leak, I have since continued to drive but taking it very easy.

I had the car jacked up this morning and inspected all the boost pipes; nothing abvious in terms of leaks using a handheld sprayer with soapy water on them. The solid inter cooler pipes are corroded but not leaking. I unplugged the recirculating valve and drove around and still the same.

Is it worth noting that I could not replicate the noise while the car was jacked up on axle stands? Revving the engine full throttle jacked up it sounds normal, only once I’m out on the road does the noise return

It’s hard to determine exactly where the source of the whooshing is coming from when inside the car driving along, but it does sound like it’s up top in the engine bay and not low down, can the PCV valve have anything to do with this?

Your feedback is appreciated