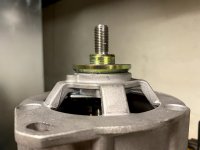

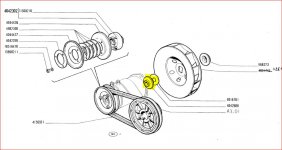

I've run into a little problem with my alternator project. The fan spacer I purchased from Ricambio doesn't have enough standoff from the rear of the alternator housing to full seat to the bearing, so fully seating it on the shaft makes it come into contact with the housing itself. The spacer has .097in standoff, but there's .125in of a gap between the housing and the bearing (pic 1). I didn't measure this at first and tapped it home (pic 2), but was thankfully able to get it off without damaging the alternator.

Is there supposed to be a washer or spacer to add sufficient standoff? Does anyone know the specific distance needed or what the installed clearance between the fan spacer and the alternator body is? It feels like the spacer should be installed the other way around, but then it's not keyed for the fan.

I'm a little stuck here, so would appreciate any help you can provide.

Thanks,

Matt

Is there supposed to be a washer or spacer to add sufficient standoff? Does anyone know the specific distance needed or what the installed clearance between the fan spacer and the alternator body is? It feels like the spacer should be installed the other way around, but then it's not keyed for the fan.

I'm a little stuck here, so would appreciate any help you can provide.

Thanks,

Matt

Attachments

Last edited: