Nowuries

New member

Hey fellow Fiat 500 friends!

First off, thanks to theHobbler for all his help in my build :wave:, and for all the great info on this site. I am in the process of rebuilding my wife's 1970 500F, and she said she wanted more power, so I took that to mean I could put in a monster...

ENGINE SPECS: 700ccm

stroke: 70mm

bore: 79.5mm

compression: 9.5

cam: 40/80

carb: Weber 40 DCOE

modified con rods

rebuilt alternator, etc.

(NOTE: I am upgrading all the other bits too as a result --brakes, suspension, axles, etc, but didn't want to go down that rabbit hole)

--brakes, suspension, axles, etc, but didn't want to go down that rabbit hole)

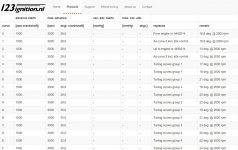

To optimize the engine setup, I also purchased a 123 ignition distributor and electronic ignition coil. I have installed the 123 ignition distributor, but it comes with the base curve for a stock 500, which will not work right... so I am looking for input on what you think the best advance curve would be based on the specs. Attached is their curve table info found on the main website and the downloadable manual: http://www.123ignition.nl/files/manuals/123manual_FIAT2R.pdf

I appreciate any assistance you can provide. :worship:

Another tidbit: I currently live at 7500 feet altitude and have heard that may affect timing a bit due to the change to the air fuel mix.

BTW, if you see/know of any major issues, please let me know!

Thanks in advance! Dax

First off, thanks to theHobbler for all his help in my build :wave:, and for all the great info on this site. I am in the process of rebuilding my wife's 1970 500F, and she said she wanted more power, so I took that to mean I could put in a monster...

ENGINE SPECS: 700ccm

stroke: 70mm

bore: 79.5mm

compression: 9.5

cam: 40/80

carb: Weber 40 DCOE

modified con rods

rebuilt alternator, etc.

(NOTE: I am upgrading all the other bits too as a result

To optimize the engine setup, I also purchased a 123 ignition distributor and electronic ignition coil. I have installed the 123 ignition distributor, but it comes with the base curve for a stock 500, which will not work right... so I am looking for input on what you think the best advance curve would be based on the specs. Attached is their curve table info found on the main website and the downloadable manual: http://www.123ignition.nl/files/manuals/123manual_FIAT2R.pdf

I appreciate any assistance you can provide. :worship:

Another tidbit: I currently live at 7500 feet altitude and have heard that may affect timing a bit due to the change to the air fuel mix.

BTW, if you see/know of any major issues, please let me know!

Thanks in advance! Dax