I know there have been threads about this before, but thought a reminder to avoid a fire would be a good idea.

When I put my 500F to bed for the winter, I noticed some petrol in the carburettor drip tray and the engine compartment had the smell of petrol. I had a good look around, but couldn't see anything obvious. I made a note to myself to check the float height before putting the car back on the road.

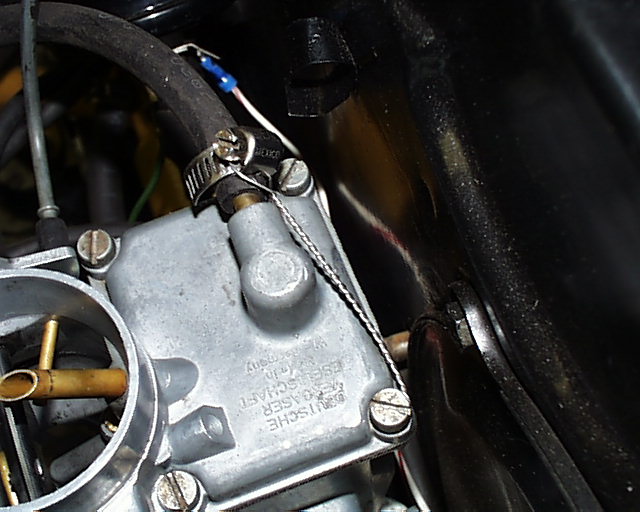

Yesterday, I removed the carburettor cover and checked and reset the float height. On reassembly, I noticed that the hose to the brass fuel inlet pipe appeared to be loose. However, on further investigation, I discovered that the brass inlet pipe was loose in the carb cover. I tapped the pipe back into place, but will be refitting the pipe with Loctite 620 or 640. As an additional safe guard, I will do what some VW owners do, and will wire the hose clips to the carb to ensure that there is positive force holding the brass inlet pipe in position. I will also be doing the same with the inlet and outlet pipes on the fuel pump. One solution would be to tap a thread and fit some threaded inlet pipes, but I don't want to risk trashing a carburettor.

The carburettor on my car looks to be reasonably new, so I wouldn't have much faith in a new one being any better and I'd still be concerned about it coming loose! It's alarming to know that a car could go up in flames because of a poor design that could have been done properly for a couple of cents!

When I put my 500F to bed for the winter, I noticed some petrol in the carburettor drip tray and the engine compartment had the smell of petrol. I had a good look around, but couldn't see anything obvious. I made a note to myself to check the float height before putting the car back on the road.

Yesterday, I removed the carburettor cover and checked and reset the float height. On reassembly, I noticed that the hose to the brass fuel inlet pipe appeared to be loose. However, on further investigation, I discovered that the brass inlet pipe was loose in the carb cover. I tapped the pipe back into place, but will be refitting the pipe with Loctite 620 or 640. As an additional safe guard, I will do what some VW owners do, and will wire the hose clips to the carb to ensure that there is positive force holding the brass inlet pipe in position. I will also be doing the same with the inlet and outlet pipes on the fuel pump. One solution would be to tap a thread and fit some threaded inlet pipes, but I don't want to risk trashing a carburettor.

The carburettor on my car looks to be reasonably new, so I wouldn't have much faith in a new one being any better and I'd still be concerned about it coming loose! It's alarming to know that a car could go up in flames because of a poor design that could have been done properly for a couple of cents!