So winter is coming here slowly, today 21 degrees and rising so far

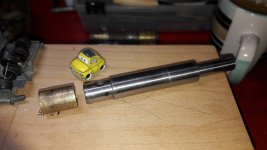

Anyway i start reconditioning the front system of the car, steering, brakes, suspension leafs, wheel wells, silent blocks etc. Ofcourse i have to do king pins myself, love that kind of stuff that need to make special tools and make you brain think. I will post some pictures here especially for the king pin renewal since this seems to be in the dark side.

Anyway i start reconditioning the front system of the car, steering, brakes, suspension leafs, wheel wells, silent blocks etc. Ofcourse i have to do king pins myself, love that kind of stuff that need to make special tools and make you brain think. I will post some pictures here especially for the king pin renewal since this seems to be in the dark side.