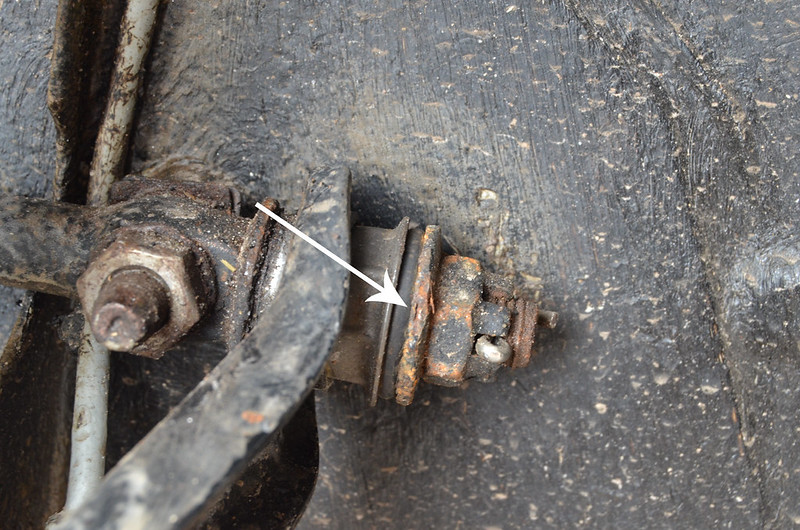

I have recently replaced the front, top suspension arms on one side because the one of the bushes was no longer gripped in the arm and was rotating in its housing.

The new arms come fitted with the bush and as with the originals, the bush has a ribbed outer casing which is held only part way into its housing. It looks like apoor design and it actually is. After only a few hundred miles the new arms have both developed the same problem. I am hoping someone has some suggestions to help with this. Perhaps I am supposed to press the bushes fully home; I'm baffled and irritated.:bang:

MAL_6656[1] by Peter Thompson, on Flickr

MAL_6656[1] by Peter Thompson, on Flickr

The new arms come fitted with the bush and as with the originals, the bush has a ribbed outer casing which is held only part way into its housing. It looks like apoor design and it actually is. After only a few hundred miles the new arms have both developed the same problem. I am hoping someone has some suggestions to help with this. Perhaps I am supposed to press the bushes fully home; I'm baffled and irritated.:bang:

MAL_6656[1] by Peter Thompson, on Flickr

MAL_6656[1] by Peter Thompson, on Flickr