nzbobc

New member

When the car is sitting and idling, say at a stop light, there's an annoying rattle in the gear shift lever.

I've deduced that the vibration coming from the engine via transmission and linkage is causing the gear shift lever to vibrate against the upper domed washer down inside the gearshift lever housing.

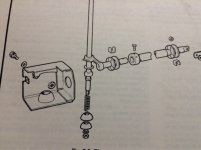

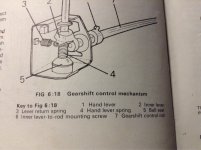

From the red arrows, the gear shift lever goes down thru the domed washer with the latter sitting on top of the rounded dome permanently affixed to the housing. The butt of the left-hand red arrow shows where the lever rubs against the washer.

My attempts to resolve the rattle has been to pack the parts with grease and a couple other lame attempts. I'm thinking that a hard plastic sleeve (e.g., delron) would work to stop the metal on metal rattle. This would require I have someone fabricate such a sleeve to match the lever and washer diameters.

Any other thoughts as to what could work? The material has to be hard wearing since the gear shift lever slides up and down against the washer when the car is put into/taken out of reverse.

It's surprising how loud this rattle is (!)

I've deduced that the vibration coming from the engine via transmission and linkage is causing the gear shift lever to vibrate against the upper domed washer down inside the gearshift lever housing.

From the red arrows, the gear shift lever goes down thru the domed washer with the latter sitting on top of the rounded dome permanently affixed to the housing. The butt of the left-hand red arrow shows where the lever rubs against the washer.

My attempts to resolve the rattle has been to pack the parts with grease and a couple other lame attempts. I'm thinking that a hard plastic sleeve (e.g., delron) would work to stop the metal on metal rattle. This would require I have someone fabricate such a sleeve to match the lever and washer diameters.

Any other thoughts as to what could work? The material has to be hard wearing since the gear shift lever slides up and down against the washer when the car is put into/taken out of reverse.

It's surprising how loud this rattle is (!)

Attachments

Last edited: