AndrewHarvey

Established member

- Joined

- Jan 17, 2015

- Messages

- 1,471

- Points

- 290

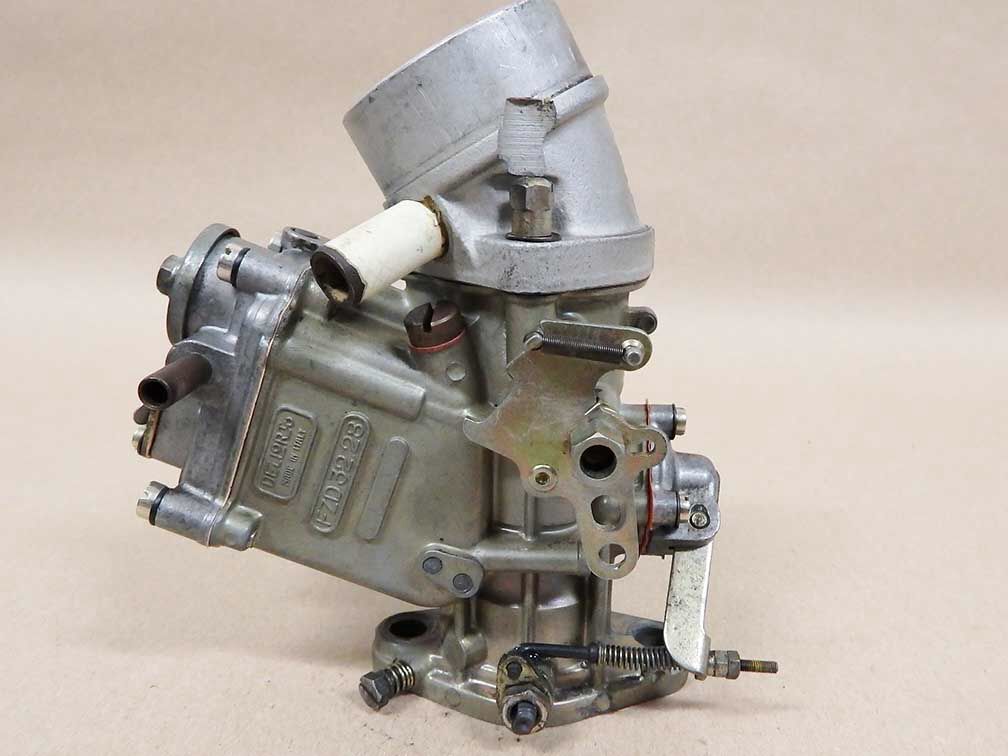

Hi the web address is:

http://www.abarth-andronico.com/carburatori e tromboncini.asp

They have many for sale....so give them a call.

I haven't finished building the engine yet...should be finished in a fortnight - i'm not intending on trying to use the choke. The bracket is missing and cannot be bought so....foot to the floor and don't stop!!!

:slayer:

http://www.abarth-andronico.com/carburatori e tromboncini.asp

They have many for sale....so give them a call.

I haven't finished building the engine yet...should be finished in a fortnight - i'm not intending on trying to use the choke. The bracket is missing and cannot be bought so....foot to the floor and don't stop!!!

:slayer: