As promised on another thread a quick update.

I had to strip the engine down because once taking the tinwork off I discovered that both base gaskets had really bad oil leaks and there appeared to be an oil leak on the front crankshaft oil seal, which all explain why the engine and gearbox were covered in such a messy oily grime.

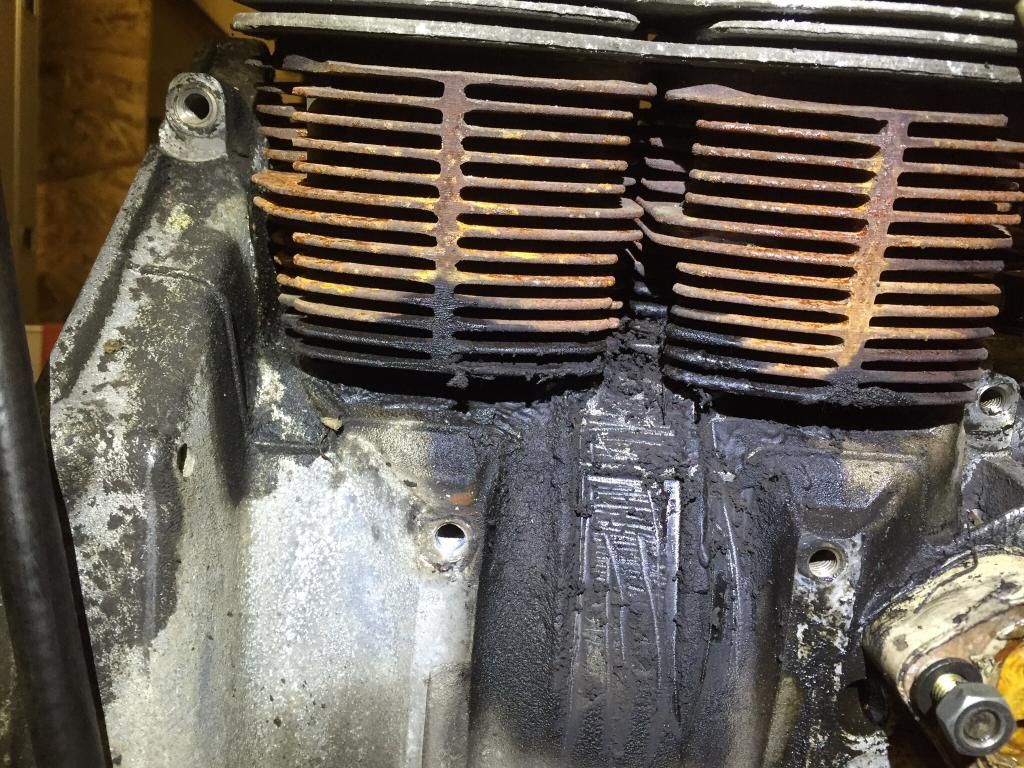

So after removing the engine cowlings I discovered this.

So the whole lot had to come apart. As you can see it is covered in oil under the cowlings.

But a bit of cleaning of the block and looking a lot healthier. The barrels and pistons were all in good condition and the crown of the pistons just needed a clean up along with the cylinder head. On the cylinder head there was a sheared bolt that had quite a lot of the bolt sticking out but it wouldn't shift, so I had to drill it out and fit a Helicoil.

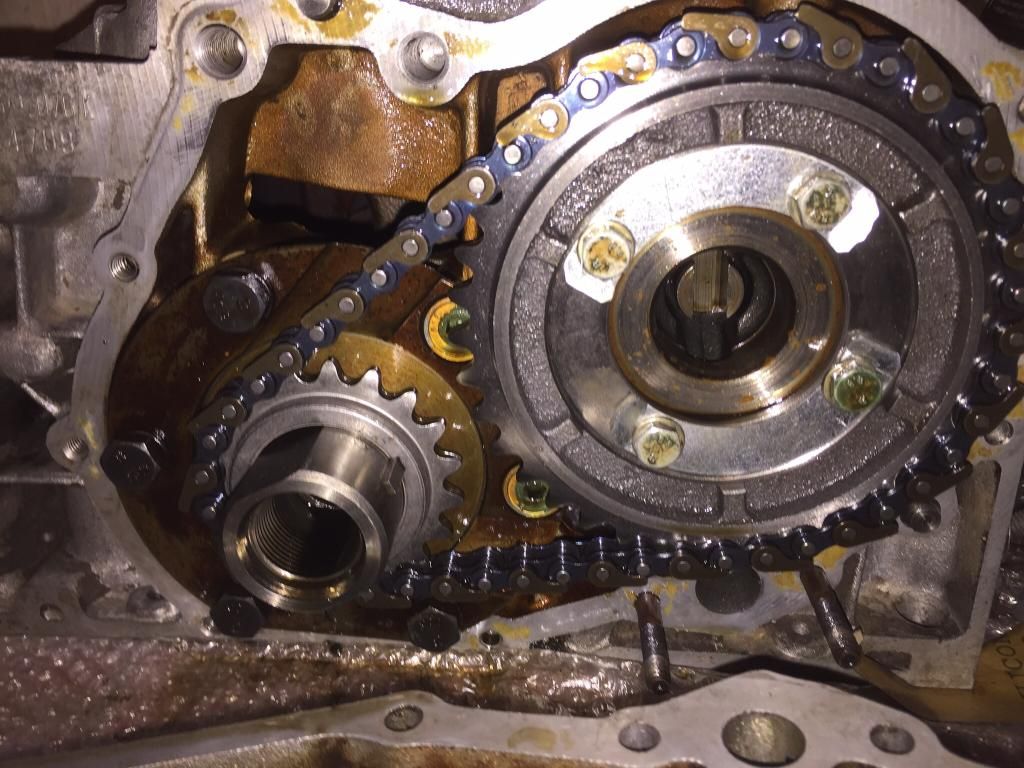

The timing chain was really sloppy and needed changing, so that was replaced along with the gears and a new oil seal put on the timing chain housing. The centrifugal oil filter was filthy I don't think it had ever been cleaned and the gasket was flat as a pancake.

Big ends were changed, main crank bearings were fine along with the rings, so all could go back together, with new gaskets and seals on the pushrod tubes. It needed a new sump as the cooling channels were all crushed from when it was removed from the car and dumped on the ground.

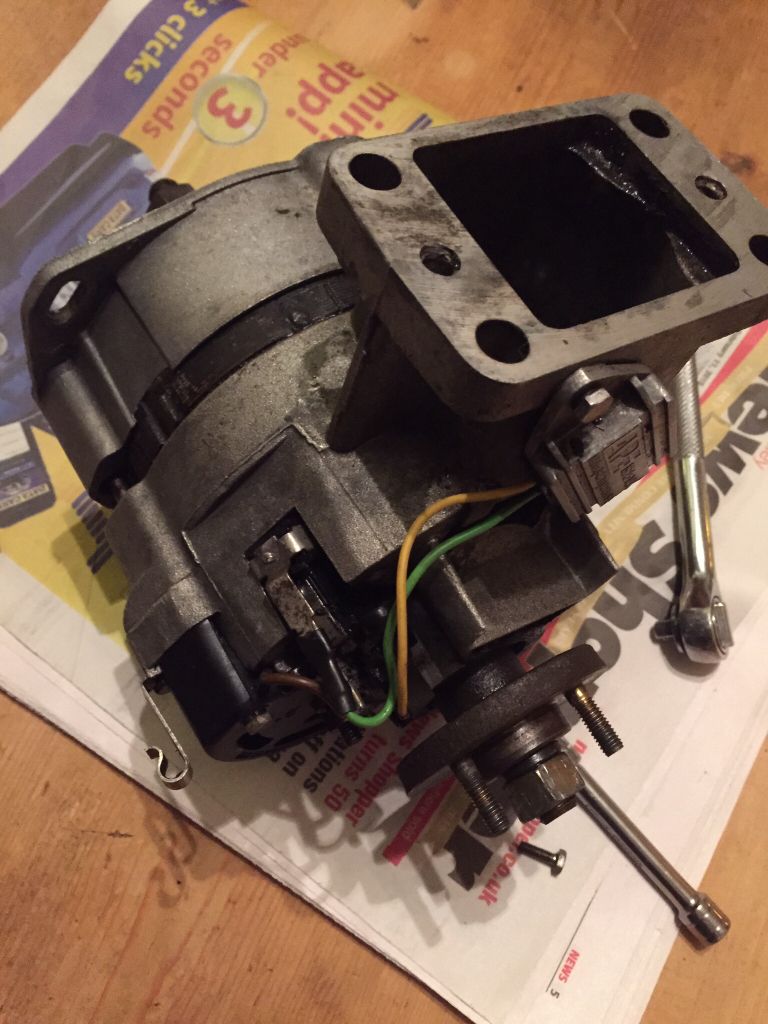

I have also done a lot of work on the driveshafts and gearbox but I will post another update on that tomorrow or I will be on here all night.