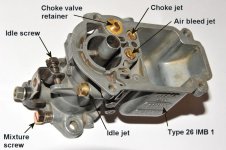

The little Weber IMBs are a very common, factory fitted, carburetor on the two cylinder, air-cooled Fiat engines. Yet despite this, there is a paucity of information available. Over my time of ownership I have collected a little bit of information about these carbies and intend to share what I have in the next few posts as well as some photos that I took recently of a carby stripdown.

The IMBs came in two varieties - the 26IMB fitted to the 500cc engines and the 28IMB fitted to the 650cc engines.

They also came in different states of tune, as indicated by the final number in the description. The 26IMB1 was fitted to the standard sedans whilst the 26IMB3 was fitted to the 'sports' engines. The 126 cars got the 28IMB3 up to November 1974 and the 28IMB1 or 28IMB10 thereafter.

They are differ in minor details only and are virtually interchangeable.

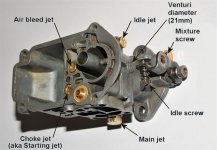

The carby is a simple downdraft single throat unit equipped with a starting (choke) device. The 26IMB has a 26mm throat diameter fitted with a non-removable 21mm primary venturi whereas the 28IMB has a 28mm throat with a 23mm primary venturi.

I have attached the section on the carburetor from the factory workshop manual (pdf). Also attached is a schematic diagram (jpg) and parts list (pdf) for the 28IMB and a picture of the major rebuild kit (jpg). Finally in this post is a comparative photo showing the size differences between the IMB and it's big brothers - the venerable DCD and the mighty DCOE.

Chris

The IMBs came in two varieties - the 26IMB fitted to the 500cc engines and the 28IMB fitted to the 650cc engines.

They also came in different states of tune, as indicated by the final number in the description. The 26IMB1 was fitted to the standard sedans whilst the 26IMB3 was fitted to the 'sports' engines. The 126 cars got the 28IMB3 up to November 1974 and the 28IMB1 or 28IMB10 thereafter.

They are differ in minor details only and are virtually interchangeable.

The carby is a simple downdraft single throat unit equipped with a starting (choke) device. The 26IMB has a 26mm throat diameter fitted with a non-removable 21mm primary venturi whereas the 28IMB has a 28mm throat with a 23mm primary venturi.

I have attached the section on the carburetor from the factory workshop manual (pdf). Also attached is a schematic diagram (jpg) and parts list (pdf) for the 28IMB and a picture of the major rebuild kit (jpg). Finally in this post is a comparative photo showing the size differences between the IMB and it's big brothers - the venerable DCD and the mighty DCOE.

Chris