You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical Gear change linkage change

- Thread starter Holeshot

- Start date

Currently reading:

Technical Gear change linkage change

berkeleyman

New member

- Joined

- Feb 23, 2013

- Messages

- 114

- Points

- 24

Hi, It isn't difficult as much as time consuming. First you need to remove the plastic tunnel tray if one is fitted, then pull back the carpet to get at the two bolt heads on the right hand side of the tunnel (drivers side on right hand drive car) my car had the carpet cut for access by previous owner, the plastic tray covers this mostly. The two aforementioned bolts should then be loostened three or four turns, then if you gently pull BACK i.e towards 2nd/4th on the gear lever you should be able to see the mounting/bolts slide forwards. Then retighten the two bolts and check the results. Don't make large adjustments or you will loose 2nd or 4th. If OK re-fit carpet etc. Good luck, I left adjustments too late resulting in 'box damage and now won't stay in first at all (3rd OK) so am about to remove the gearbox to check for damage. What is it they say, "a stitch in time!"

- Joined

- May 27, 2010

- Messages

- 416

- Points

- 137

When you select 1 and 3, is there just a little resistance when you pull the lever back to neutral? Does the lever feel as though it 'clicks' in and out?

There should be enough adjustment in the gear lever mounting to get you out of trouble. If there are issues with selecting 1st and 3rd you need to adjust the mounting forward and from your note you have done this. From memory it may be possible to try and adjust too far forward, and this would allow the gear stick itself to rub up against the cutout in the top of the tunnel. This in effect hinders the gear selection as well.

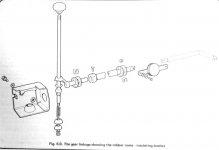

In the photo you can see the rubber disk that forms part of the linkage. This rubber gets soft, perishes and allows too much movement. Also, if the bolts that hold this linkage in place are loose, you will also have an issue selecting gears. It may pay you to look under the car look at this linkag and see if there is an issue there.

It is simple (but as always, fiddly) to remove the lever assembly and the rod that runs in the tunnel.

Let us know what you find under the car and we can take it from there.

Joe R

There should be enough adjustment in the gear lever mounting to get you out of trouble. If there are issues with selecting 1st and 3rd you need to adjust the mounting forward and from your note you have done this. From memory it may be possible to try and adjust too far forward, and this would allow the gear stick itself to rub up against the cutout in the top of the tunnel. This in effect hinders the gear selection as well.

In the photo you can see the rubber disk that forms part of the linkage. This rubber gets soft, perishes and allows too much movement. Also, if the bolts that hold this linkage in place are loose, you will also have an issue selecting gears. It may pay you to look under the car look at this linkag and see if there is an issue there.

It is simple (but as always, fiddly) to remove the lever assembly and the rod that runs in the tunnel.

Let us know what you find under the car and we can take it from there.

Joe R

Attachments

Last edited:

Hey guys, thanks for the speedy reply

I've already replaced the part with the rubber disc (as the photo) for a new one. Also have pushed the linkage as far forward(towards 1st/3rd) as it'll go on those 2 adjuster bolts.

This is the only position it'll stay in 1st & 3rd. It's so far fwd that I've had to cut away the steel frame around the rubber gear lever gaitor otherwise it prevents clean selection & springs it back out of gear into neutral.

This is OK-ish for the short term but failing any remedy, would like to know whether putting a whole new linkage in would cure the problem(can't understand how a 67000mile car can wear a linkage out) and how difficult it would be to do the job.

Hope you understand what Im on about :/

Cheers,

Hilton

I've already replaced the part with the rubber disc (as the photo) for a new one. Also have pushed the linkage as far forward(towards 1st/3rd) as it'll go on those 2 adjuster bolts.

This is the only position it'll stay in 1st & 3rd. It's so far fwd that I've had to cut away the steel frame around the rubber gear lever gaitor otherwise it prevents clean selection & springs it back out of gear into neutral.

This is OK-ish for the short term but failing any remedy, would like to know whether putting a whole new linkage in would cure the problem(can't understand how a 67000mile car can wear a linkage out) and how difficult it would be to do the job.

Hope you understand what Im on about :/

Cheers,

Hilton

berkeleyman

New member

- Joined

- Feb 23, 2013

- Messages

- 114

- Points

- 24

Silly me, sorry, didnt read the question properly, seems you are at the same stage as me. Good luck and keep us posted

- Joined

- May 27, 2010

- Messages

- 416

- Points

- 137

Even though I quoted the manual, it always confused me that you move the lever section forward for one and three. I would have thought moving it back would have been the solution. Any chance you could try that? You should not have to cut the surround to accommodate the lever.

Joe R

Joe R

jolly500

Member

Hi,

I read somewhere that the easiest way of setting the gear lever position is to loosen the 2 bolts in the side of the central tunnel, put the gearbox into Reverse and tighten the bolts. I have just done that with mine after refitting the engine and gearbox and it worked first time.

Having said that, my car is a 'N' model from 1958 and has a solid rod connecting the gear lever to gearbox without the rubber disc shown in the pic.

Might still be worth a try?

Steve

I read somewhere that the easiest way of setting the gear lever position is to loosen the 2 bolts in the side of the central tunnel, put the gearbox into Reverse and tighten the bolts. I have just done that with mine after refitting the engine and gearbox and it worked first time.

Having said that, my car is a 'N' model from 1958 and has a solid rod connecting the gear lever to gearbox without the rubber disc shown in the pic.

Might still be worth a try?

Steve

Yeah sorry for confusion - my initial question was very briefly put

Thanks for the relies tho.

Much further back and it won't even select 1st or 3rd.

Without the gaitor on at all it selects fine but way too far forward. There is a cutout in the tunnel that is partially covered with the gaitor & frame which interrupts the lever's action and tends to push it back. I cut the frame which helps and works OK but lacks a really easy positive feel. Plus, with the plastic tray in place it goes back to square one.

I just wondered before I buy a new linkage whether it's a job best left to someone with special tools or is it an ahem, 'simple' job of un bolting the 2 adjuster bolts at the front and disconnecting the linkage to the rubber bushed connector as per Joe's photo at the back then pulling it out from the tunnel. Fitting presumably being the fiddle of threading the rod back out the back.

Any ideas?

Thanks again

Thanks for the relies tho.

Much further back and it won't even select 1st or 3rd.

Without the gaitor on at all it selects fine but way too far forward. There is a cutout in the tunnel that is partially covered with the gaitor & frame which interrupts the lever's action and tends to push it back. I cut the frame which helps and works OK but lacks a really easy positive feel. Plus, with the plastic tray in place it goes back to square one.

I just wondered before I buy a new linkage whether it's a job best left to someone with special tools or is it an ahem, 'simple' job of un bolting the 2 adjuster bolts at the front and disconnecting the linkage to the rubber bushed connector as per Joe's photo at the back then pulling it out from the tunnel. Fitting presumably being the fiddle of threading the rod back out the back.

Any ideas?

Thanks again

Last edited:

If the bush that the rod runs in behind the gear lever is shot then selection of all gears is pretty much impossible. The bush presses into the gear lever housing. You do not need any special tools to fix it and it is very unlikely that you need a complete new gear linkage. I may still have a spare one here plus I have a number of 500 & 126 gearboxes plus some spare internals. Where in London are you as I am about 5 miles outside of junction 18 of the M25?

Thanks Toshi.

I've replaced the rubber disc/plate already I'm afraid.

It's true: I can't understand how a linkage who's action seems fine can be worn to such an extent that it's solid rod needs adjusting fwd by over 1/2".

Could I just shorten the rubber disc plate a little or is that really stupid?

Could it be the wrong rubber disc plate for my model(500L)? Do they vary?

I'm in Lewisham (nearest J2/3 on M25)

I've replaced the rubber disc/plate already I'm afraid.

It's true: I can't understand how a linkage who's action seems fine can be worn to such an extent that it's solid rod needs adjusting fwd by over 1/2".

Could I just shorten the rubber disc plate a little or is that really stupid?

Could it be the wrong rubber disc plate for my model(500L)? Do they vary?

I'm in Lewisham (nearest J2/3 on M25)

Sorry for my confusion Toshi.

So do you mean the bush in the linkage housing is replaceable?

All gears do actually select OK when the housing is pushed forward to the absolute limit.

Yeah - J2/3 is the other side of the world, lol.

So do you mean the bush in the linkage housing is replaceable?

All gears do actually select OK when the housing is pushed forward to the absolute limit.

Yeah - J2/3 is the other side of the world, lol.

Hi holeshot,

The book is correct when it advises forward movement of the selector assembly if you are having difficulty engaging 1st/3rd gear. This is because the lever is pivoted from the bottom so when you push it forward to engage 1st/3rd it pulls the control rod forward also and engages the gears.

If your assembly is already at its forward limit (or beyond in your case) and you still can't engage 1st/3rd then effectively your control rod is 'too long'. I would normally say that the circular rubber vibration insulator (or whatever it's called) is kaput, but you've replaced it and still have a problem.

I wouldn't think that the linkage itself is an issue as there is really nothing in there to wear apart from a couple more small bushes which have nothing to do with the effective length of the control rod.

I also assume that the engine is mounted correctly and not sagging on its two front supports and that your gear lever isn't bent ...

Bit of a mystery - sorry. Is it possible to post photos of the underside of the car?

Chris

PS: When I set up my car, I used the advice given by Steve (jolly500) and adjusted it with reverse gear selected. This won't help you though.

The book is correct when it advises forward movement of the selector assembly if you are having difficulty engaging 1st/3rd gear. This is because the lever is pivoted from the bottom so when you push it forward to engage 1st/3rd it pulls the control rod forward also and engages the gears.

If your assembly is already at its forward limit (or beyond in your case) and you still can't engage 1st/3rd then effectively your control rod is 'too long'. I would normally say that the circular rubber vibration insulator (or whatever it's called) is kaput, but you've replaced it and still have a problem.

I wouldn't think that the linkage itself is an issue as there is really nothing in there to wear apart from a couple more small bushes which have nothing to do with the effective length of the control rod.

I also assume that the engine is mounted correctly and not sagging on its two front supports and that your gear lever isn't bent ...

Bit of a mystery - sorry. Is it possible to post photos of the underside of the car?

Chris

PS: When I set up my car, I used the advice given by Steve (jolly500) and adjusted it with reverse gear selected. This won't help you though.

Attachments

Thanks Chris.

It's sure got me scratching my head.

My first thought was a worn linkage but like you say; how can the bushes etc wear to such a degree?

The engine & box are 650 based and newly fitted with all new parts.

Do you think that relocating a hole in the link plate to make it slightly shorter may do the trick?

At a bit of a loss.......

It's sure got me scratching my head.

My first thought was a worn linkage but like you say; how can the bushes etc wear to such a degree?

The engine & box are 650 based and newly fitted with all new parts.

Do you think that relocating a hole in the link plate to make it slightly shorter may do the trick?

At a bit of a loss.......

Shortening the control rod may help. According to the photo above, the rod is in two sections joined by a collar - you might find you can adjust it there.

It might pay you to remove the lever assembly again and see how much length you have available.

I have a 126 transmission in my car actuated by a standard 500F gear lever/control rod assembly that works perfectly, so there is every reason that yours should too.

I had a spare lever assembly at home but I gave it away to a guy who was rebuilding a 500 so I can't post you any other photos apart from what I find in books and manuals.

Chris

It might pay you to remove the lever assembly again and see how much length you have available.

I have a 126 transmission in my car actuated by a standard 500F gear lever/control rod assembly that works perfectly, so there is every reason that yours should too.

I had a spare lever assembly at home but I gave it away to a guy who was rebuilding a 500 so I can't post you any other photos apart from what I find in books and manuals.

Chris

Last edited:

It is not so much that the bushes wear. They tend to harden with age and break up. Apart from the bush in the gear lever assembly there should also be an identical one supporting the long rod at the gearbox end where the rod exits the rear of the tunnel.

Thanks again for the replies guys.

Think the only way is to remove it and check nothing appears to have slipped.

Will check the collar join. Maybe there's a way of shortening it there. Nothing's impossible I s'pose.

Think the only way is to remove it and check nothing appears to have slipped.

Will check the collar join. Maybe there's a way of shortening it there. Nothing's impossible I s'pose.

jjoldskool

New member

- Joined

- Jun 9, 2019

- Messages

- 1

- Points

- 0

Did you ever get to the bottom of this and fix it? I am having the exact same problem ...the only way I can select all 4 gears is to adjust it beyond the adjustment hole (take out the bolt and move it past where the elongated hole is ...some how making the hole biggges seems probably the wrong thing to do...pls help!

the hobbler

Distinguished member

- Joined

- Jul 25, 2012

- Messages

- 4,069

- Points

- 1,011

Check my comments in the recent thread "Clutch drag" and the necessity for the engines position to be checked. For adjustment of 1st & 3rd gears, the gear -change support 'box' is moved FORWARD, and for adjustment of 2nd, 4th & reverse, the support 'box' is moved BACK. If you run out of adjustment slot, there is something fundamentally wrong somewhere. When I had work done on the rear of my 500, the new shape of one of the rear wings dictated that I put a thin (1.5mm) shim between the body and the rear cross-member which, because it moved the engine back a little bit, effected selection of 2nd/4th/rev. So, as you can see, it doesn't take much to effect gear selection.