- Joined

- Mar 5, 2012

- Messages

- 156

- Points

- 32

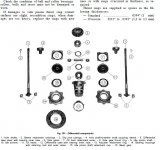

I'm rebuilding my 126 diffeential and have struck a couple of snags tonight that I'd appreciate some advice on.

First, and no biggie here, I found that the 500R axles I am using needed a small adjustment to make them fit. Specifically the axle trunions - or pins I think some people call them - had a very slight difference in their end radius to the original 126 ones. This meant I had to gently grind the pins down ever so slightly so that they fitted into the side gears. Anyone else had this issue?

Second, and this is the major issue, I appear to have too much play in the side gear pinion assembly. The side gears float in and out by about .5mm. I have 1.3mm bronze thrust washers fitted. These are what came in the differential from the factory and are the thickest ones listed in the parts book, but it would appear I need to either stack in some additional thinner thrust washers to take up the slack, or make/source a set of thicker thrust washers. Or I guess I could buy a new side gear/pinion assembly. Trouble is I have never seen either the washers or replacement side gears for sale and even a google search finds no reference!

Does anyone with any experience with this know if the .5m slack in the mesh is normal? I'd really like to reduce it so that the gear teeth are loaded up further towards the stronger root of the tooth. Also, with this amount of slack there is no effective rolling torque, which surely can't be right?

Cheers Roger

First, and no biggie here, I found that the 500R axles I am using needed a small adjustment to make them fit. Specifically the axle trunions - or pins I think some people call them - had a very slight difference in their end radius to the original 126 ones. This meant I had to gently grind the pins down ever so slightly so that they fitted into the side gears. Anyone else had this issue?

Second, and this is the major issue, I appear to have too much play in the side gear pinion assembly. The side gears float in and out by about .5mm. I have 1.3mm bronze thrust washers fitted. These are what came in the differential from the factory and are the thickest ones listed in the parts book, but it would appear I need to either stack in some additional thinner thrust washers to take up the slack, or make/source a set of thicker thrust washers. Or I guess I could buy a new side gear/pinion assembly. Trouble is I have never seen either the washers or replacement side gears for sale and even a google search finds no reference!

Does anyone with any experience with this know if the .5m slack in the mesh is normal? I'd really like to reduce it so that the gear teeth are loaded up further towards the stronger root of the tooth. Also, with this amount of slack there is no effective rolling torque, which surely can't be right?

Cheers Roger