timgarman

Established member

Hi Folks

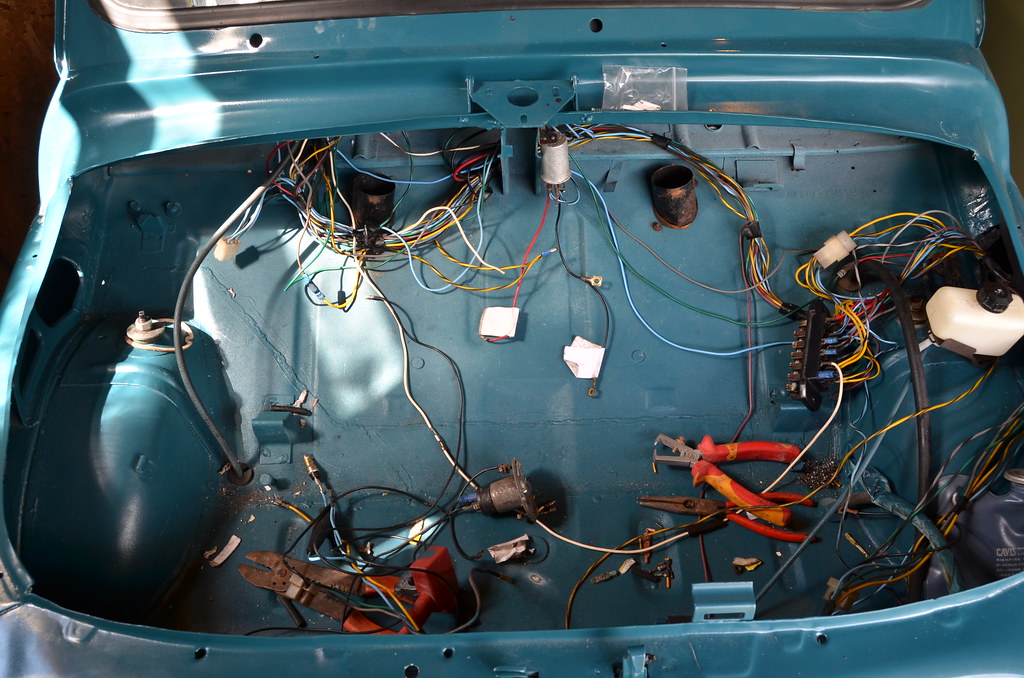

I'm just at the stage of laying out the wiring loom from my 500F, in fact, we have some of it in the car now. It was removed some 3 years ago and carefully labelled. Most of these have now fallen off or the notes have become unreadable... I'm hoping this is a familiar story... or it may just be sheer stupidity. :bang:

Can anyone upload, or direct me to some photos that show some of the significant wiring points. For example, under the bonnet coming from the fusebox. I also need to know which hole under the bonnet these pass through, there are a couple of possibilities.

Also, wires extruding from the empty tail light holes would be helpful.

I do have wiring diagrams, but we are talking 50 year old wiring, with central locking and an alarm added (both now removed) plus 50 years of grime and tinkering. It also doesn't help that my genius mechanical friend is sadly colour blind.

Thanks in advance for any help anyone can give.

Tim

I'm just at the stage of laying out the wiring loom from my 500F, in fact, we have some of it in the car now. It was removed some 3 years ago and carefully labelled. Most of these have now fallen off or the notes have become unreadable... I'm hoping this is a familiar story... or it may just be sheer stupidity. :bang:

Can anyone upload, or direct me to some photos that show some of the significant wiring points. For example, under the bonnet coming from the fusebox. I also need to know which hole under the bonnet these pass through, there are a couple of possibilities.

Also, wires extruding from the empty tail light holes would be helpful.

I do have wiring diagrams, but we are talking 50 year old wiring, with central locking and an alarm added (both now removed) plus 50 years of grime and tinkering. It also doesn't help that my genius mechanical friend is sadly colour blind.

Thanks in advance for any help anyone can give.

Tim