turbo500

Member

- Joined

- Mar 20, 2013

- Messages

- 251

- Points

- 118

I believe from the factory, the 500 came with felt cutouts that went behind the rear seats top & bottom.

I've noticed that several online stores sell different materials for sound deadening in the 500s.

Here are the options I've seen:

Felt roll (popular on classic cars)

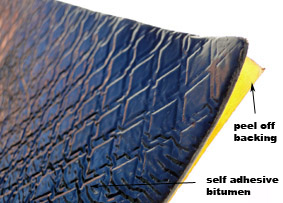

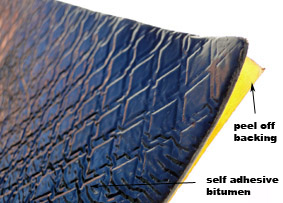

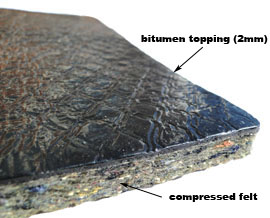

Bitumen coated sheets for sale

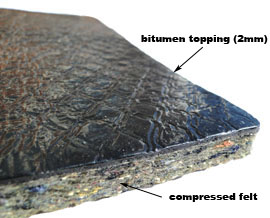

bitumen+felt (slightly thicker)

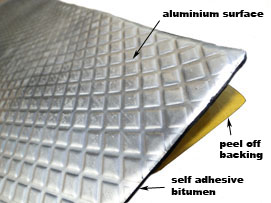

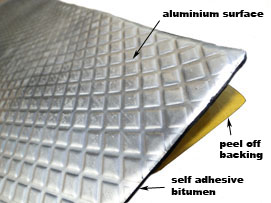

aluminium rolls with different properties (heat/noise/etc)

I did some research as well, and there are some other interesting materials that people recommend, one of which is Closed Cell PE Foam. Some suggested that higher end cars are lined with copious amounts of this stuff, adding large amounts of weight, getting in return a very quiet drive.

Example of Closed Cell PE with adhesive backing

Now, obviously, the 500 will never be a silent car, it was not designed with this in mind. But I know several people on here have used various types of insulation.

I was looking to get some feedback on anyone who has put in new sound deadening, to see what their results are and if anyone has anything to say about the various materials available.

I'm considering using this Closed Cell PE, since it's thicker than aluminium sheets, but haven't seen many classic car owners use it. Jute seems to be outdated as it has the downside of being thick, and absorbing moisture. So with all these newer materials, I'm sure there's something that can help.

Ciao

I've noticed that several online stores sell different materials for sound deadening in the 500s.

Here are the options I've seen:

Felt roll (popular on classic cars)

Bitumen coated sheets for sale

bitumen+felt (slightly thicker)

aluminium rolls with different properties (heat/noise/etc)

I did some research as well, and there are some other interesting materials that people recommend, one of which is Closed Cell PE Foam. Some suggested that higher end cars are lined with copious amounts of this stuff, adding large amounts of weight, getting in return a very quiet drive.

Example of Closed Cell PE with adhesive backing

Now, obviously, the 500 will never be a silent car, it was not designed with this in mind. But I know several people on here have used various types of insulation.

I was looking to get some feedback on anyone who has put in new sound deadening, to see what their results are and if anyone has anything to say about the various materials available.

I'm considering using this Closed Cell PE, since it's thicker than aluminium sheets, but haven't seen many classic car owners use it. Jute seems to be outdated as it has the downside of being thick, and absorbing moisture. So with all these newer materials, I'm sure there's something that can help.

Ciao

Last edited: