In this whole episode I have not had any codes at all...

However, I have changed Crankshaft sensor, Fuel filter, cleaned EGR assembly, and got a timing alignment tool and a Cam sensor on the way. The computer/code reader has told me diddly squat.

So while I'm waiting for parts to arrive, and that I now have no choice in resetting the timing from scratch, a few of things I'm not sure about.

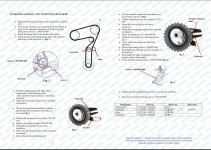

1. How do I know when the 1st cylinder is at TDC.. There is talk about rotating through 2 revolutions etc

2. Do I need a puller to get the camshaft pulley off, is it keyed, or do I have to note the exact position, considering it has marks.

3. How do I release the tension of the belt.

As you can tell, I'm not confident in this at all. When I was doing timing on cars, everything was easy....sparkplug out, pencil depth to get TDC, strobe on the crankshaft wheel, notch on the outside case...valves shut by gap in cams...no sensors, no computers to mess things up...job done.. Why did they have to complicate things