Hi,

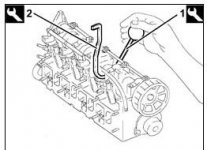

My service manual syas the tappets need adjusting a good few thousand miles ago, i Know this hasn't been done.

Can any one walk me through how to check the clearences and how to replace the shims?

any help would be much appreciated.

Stu

My service manual syas the tappets need adjusting a good few thousand miles ago, i Know this hasn't been done.

Can any one walk me through how to check the clearences and how to replace the shims?

any help would be much appreciated.

Stu