- Joined

- Jan 16, 2005

- Messages

- 10,608

- Points

- 1,450

Hi guys

Not had much luck in the Punto section with this so I thought I'd ask in a section where they have lots more JTDs

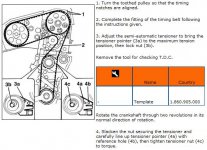

Basically I having problems tensioning my new cam belt. I can't seem to make the tensioner stay at the tension I set. That's with the tensioner bolted fully onto the block. The tensioner is new.

I'm a bit stumped TBH as to why I can't set the tensioner up properly. I have found a pin/dowel on the block which the slit in the tensioner backplate can fit over. Do I use this as a stop for the silver pointer then lever the angled tab to set the tensioner?

TIA

Not had much luck in the Punto section with this so I thought I'd ask in a section where they have lots more JTDs

Basically I having problems tensioning my new cam belt. I can't seem to make the tensioner stay at the tension I set. That's with the tensioner bolted fully onto the block. The tensioner is new.

I'm a bit stumped TBH as to why I can't set the tensioner up properly. I have found a pin/dowel on the block which the slit in the tensioner backplate can fit over. Do I use this as a stop for the silver pointer then lever the angled tab to set the tensioner?

TIA