Ok Let's see if i can explain

Two things to appreciate first.

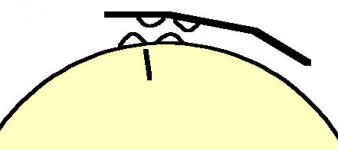

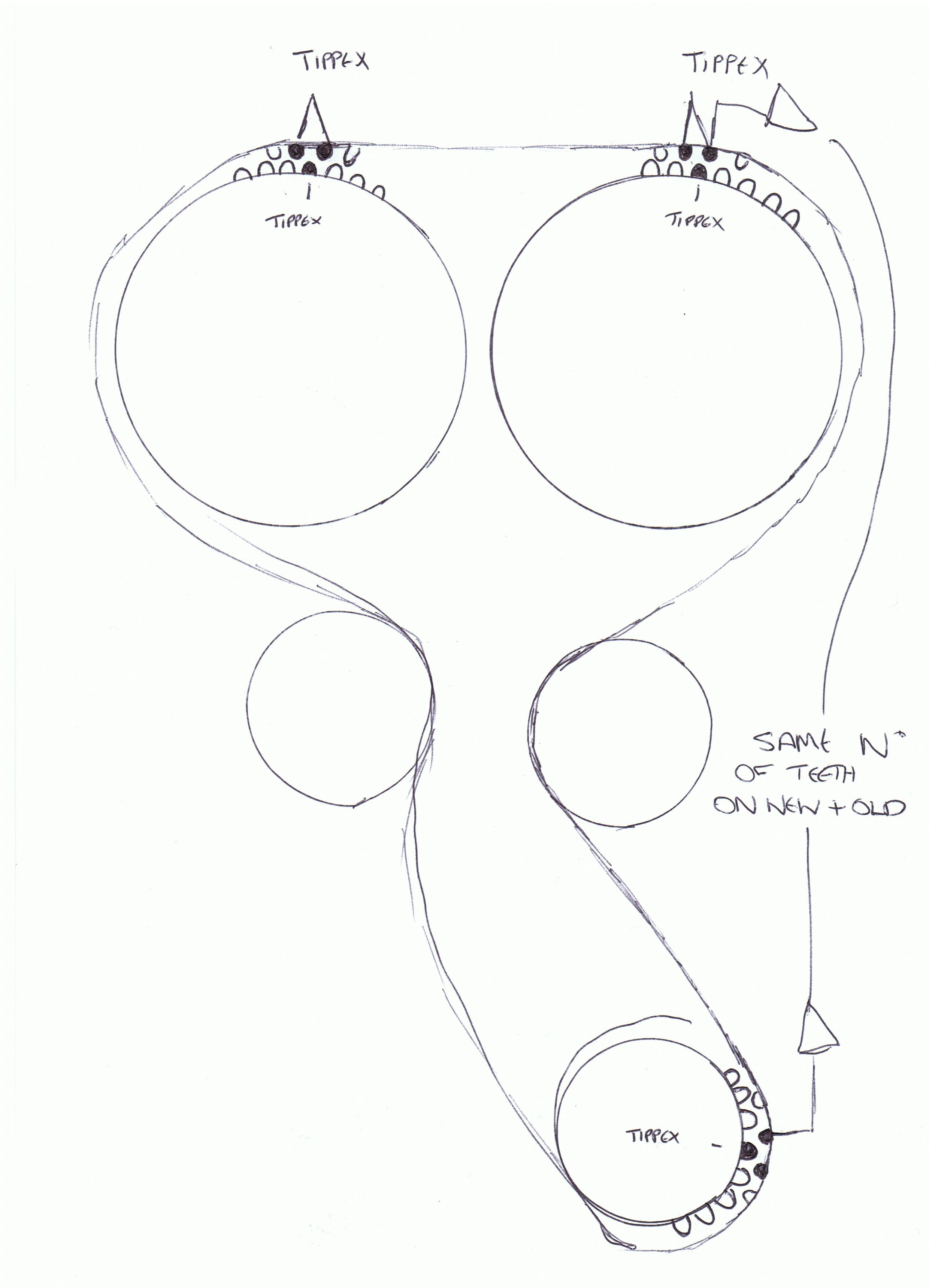

1 Belts do stretch, not by much but they do and it doesn't take much as we'll see to make big differences in the valve timing. That's why the recommended method of installing a new cam belt is to put it on maximum possible tension at the tensioner first, then rotate the engine a few times to straighten and stretch the belt and THEN set the tensioner to the correct tension. Then recheck the crank and cam positions again

2 Undeniably, if the 1.6 engine was running fine to start with and tippex marks are used to mark the crank and camshaft positions and if the marks are exactly the same when you finish the job then the engine will run the same as before.

So what goes wrong?

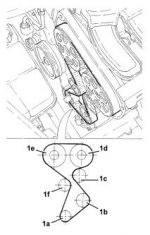

If we say there are 30 teeth to a cam sprocket then each tooth will be 360/30 degrees = 12 degrees. That means half a tooth out = 6 degrees error.

Ok so let's see what happens

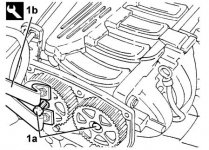

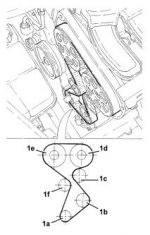

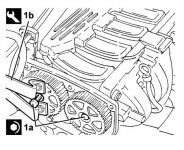

You wind the new cambelt over the crank sprocket at the bottom and work your way anticlockwise up to the top right cam sprocket.

But the belt teeth and the sprocket don't quite line up. What are you going to do?

Not much choice, you have to move the whole camshaft with sprocket a fraction to align the sprocket to the belt. You didn't move it much, it's almost in line with your tippex marks, it looks ok, it's as near as you can get it but in the worst case scenario you're 1/2 a tooth out-6 degrees.

And the same thing could be happening with the remaining camshaft

The mistake is that you've moved the whole camshaft to align with the belt rather than keep the cam still and move the cam sprocket to align with the belt

In the best case scenario you have put the new belt on and aligned things exactly the same as the were. But if the camshafts were out of alignment by even a fraction to start with then they'll be out of alignment to the same amount again when you've finished as you have used the tippex marks to check that it is the same

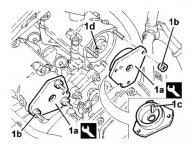

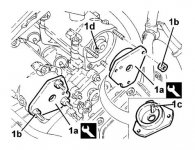

Now take the approved method

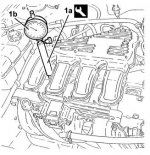

The crankshaft is exactly at TDC

The cams are exactly in position

The cam sprockets have been rotated on their camshafts until they align perfectly with the belt and THEN tightened

Only now is everything guaranteed to be exactly as it should.

Mine had a sickly hesitation at low rev pick up- always at 1500rpm- bloody nuisance when crawling along in traffic. After a correctly carried out cambelt change and realigment all was as it should be