shiningliao

New member

- Joined

- Jan 6, 2008

- Messages

- 84

- Points

- 18

I am planning to change the timing belt by myself. Some special tools are required to do the job. Any one know how to get them cheaply? Or use some alternative solutions...

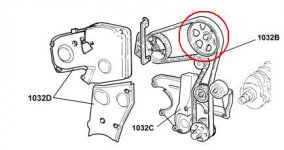

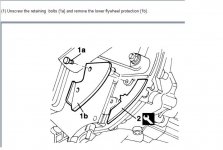

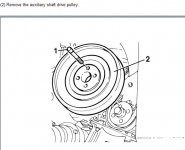

1). Fly wheel holding tool (The one at the right hand side of the picture)

part no.: 1860898000

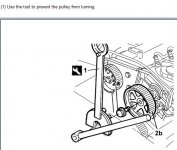

2). Crankshaft timing tool (The one at the top of the picture)

part no.: 1860905000

3). Calibrated screw (The black screws at the top of the picture)

part no.: 1860905010

Price quote from FIAT is around £60 pounds. Searching through internet found the similiar one is £85+ (becuase it contains other stuff)

Anyone get any idea to get it cheaply? In fact, I only need to "rent it" for awhile.

1). Fly wheel holding tool (The one at the right hand side of the picture)

part no.: 1860898000

2). Crankshaft timing tool (The one at the top of the picture)

part no.: 1860905000

3). Calibrated screw (The black screws at the top of the picture)

part no.: 1860905010

Price quote from FIAT is around £60 pounds. Searching through internet found the similiar one is £85+ (becuase it contains other stuff)

Anyone get any idea to get it cheaply? In fact, I only need to "rent it" for awhile.