Hi folks

I've just changed the cambelt, tensioner and waterpump on my 100HP and would like to know if I also have to do a phonic relearn as with some other Fiat models?

The engine is running smoothly and normally as it was before I did the change. There's no warning lights.

It was quite a time consuming job, the inner engine mount is a very tricky to remove and refit with 6 horizontal bolts and very little space between the engine and the chassis.

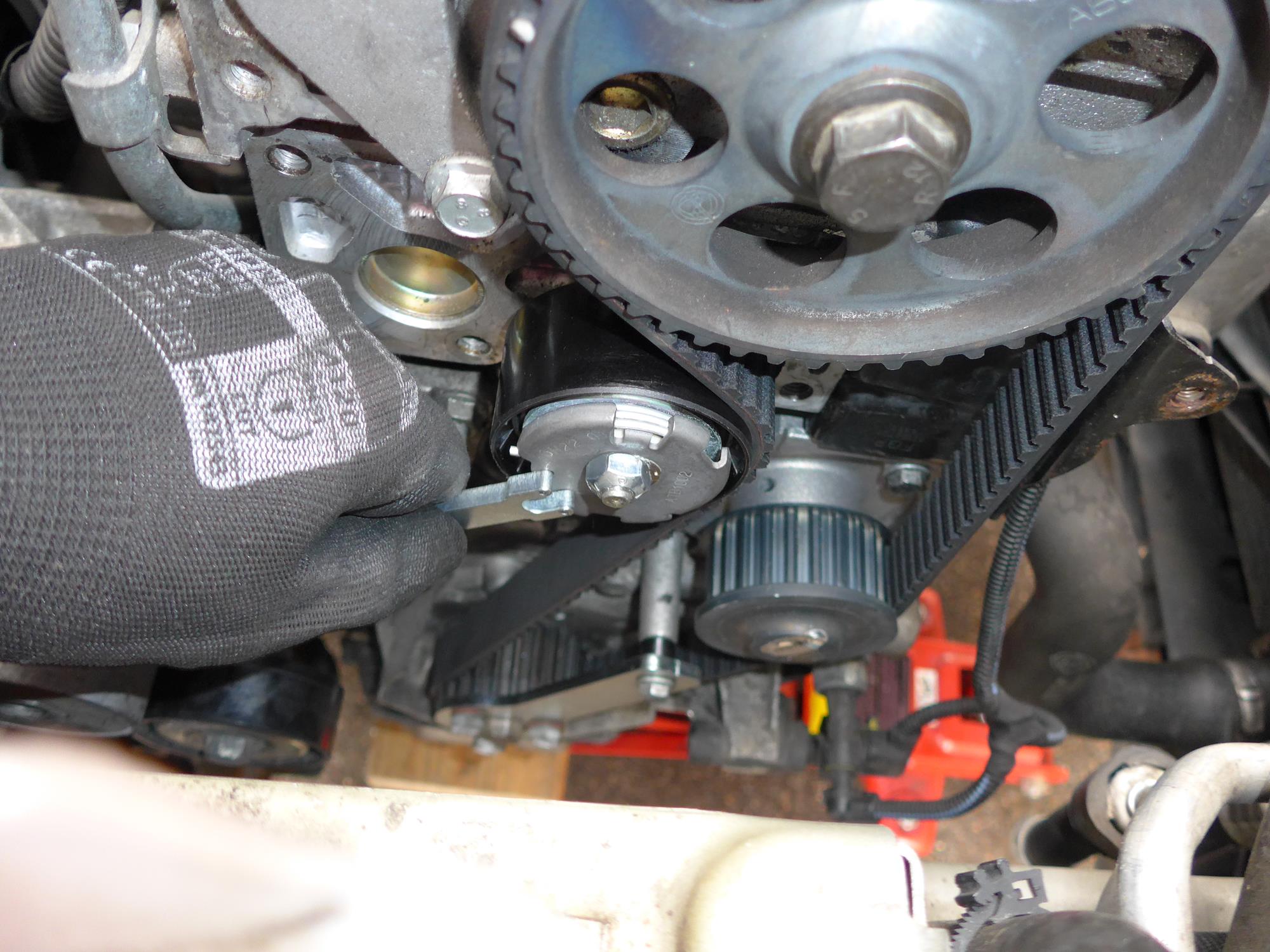

I used a toolkit with the measuring rods and locking tools. I found the wedge tool that locks the camshaft pulley didn't always engage properly with the teeth due to the pulley position. I had to make a pulley holding tool from steel strip to secure it when undoing/torquing the pulley bolt (120Nm).

Did have a bit of a fright when I started the car after everything was back together. The car didn't want to start and was running very roughly. Ahhhh

It turned out one of the coil packs hadn't seated firmly enough on the sparkplug. :bang:

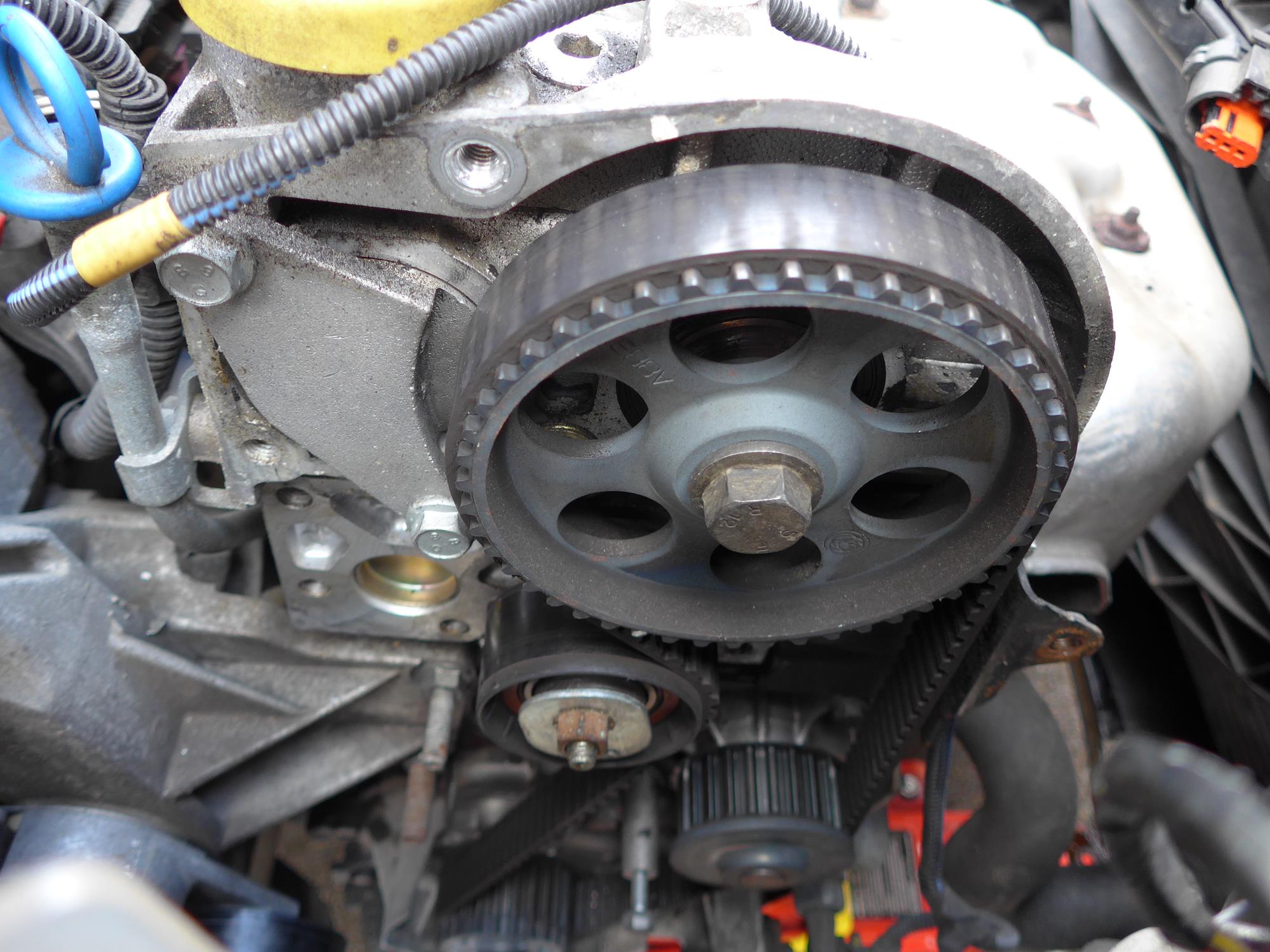

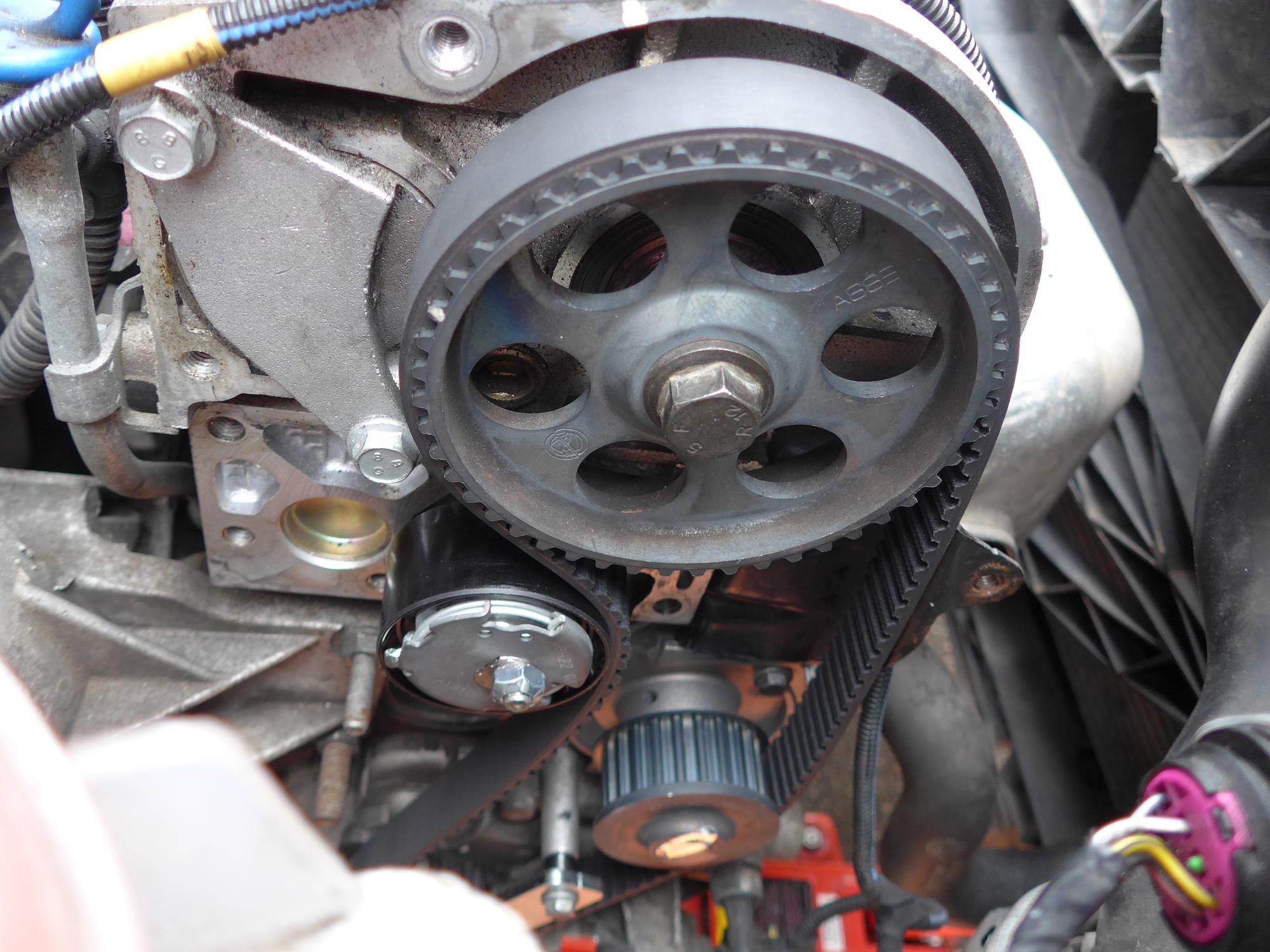

I've taken a few photos as I did it and will upload them to the forum soon.

I've just changed the cambelt, tensioner and waterpump on my 100HP and would like to know if I also have to do a phonic relearn as with some other Fiat models?

The engine is running smoothly and normally as it was before I did the change. There's no warning lights.

It was quite a time consuming job, the inner engine mount is a very tricky to remove and refit with 6 horizontal bolts and very little space between the engine and the chassis.

I used a toolkit with the measuring rods and locking tools. I found the wedge tool that locks the camshaft pulley didn't always engage properly with the teeth due to the pulley position. I had to make a pulley holding tool from steel strip to secure it when undoing/torquing the pulley bolt (120Nm).

Did have a bit of a fright when I started the car after everything was back together. The car didn't want to start and was running very roughly. Ahhhh

It turned out one of the coil packs hadn't seated firmly enough on the sparkplug. :bang:

I've taken a few photos as I did it and will upload them to the forum soon.