I had this exact same problem on my Tipo over 20 years ago and I took the car to a mobile engine tuning guy in Macclesfield and after idling the engine for nearly an hour while he ran loads of diagnostic tests he declared there was no fault,then just as he was about to lower the bonnet the engine stalled,he ran more tests and said it was the fuel cutoff solenoid causing the problem and to prove the point he cut the plunger off and the fault was cured,no more stalling when I pulled up at a junction, however when I bought a new solenoid the same problem re occurred so in the end I just put the solenoid back with the plunger cut off,when you drive like I do you don't worry about fuel consumption !

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical 1988 mk2 Fiat Panda

- Thread starter Pandateria

- Start date

Currently reading:

Technical 1988 mk2 Fiat Panda

Pandateria

New member

- Joined

- May 24, 2015

- Messages

- 32

- Points

- 11

Yep, that's exactly the problem I've got, and my mechanic also ran a load of tests then told me there was no problem.

Right well I am an electronics engineer not a car expert so don't take what I say as gospel,but the solenoid seems to close by some sort of switch possible two contacts making on the carburetor when the throttle is closed cutting off the fuel supply,so if you were to unplug the fuel cut off solenoid and connect the 2 wires of the solenoid valve directly to the car battery this will keep the solenoid open when when decelerating ,you could try this,it would prove the point rather than cutting off the plunger as there is no turning back when you have done this .

Pandateria

New member

- Joined

- May 24, 2015

- Messages

- 32

- Points

- 11

It would be a good way to find out, and as you say, a better option. I'll let you know the outcome. Thanks.

Right well I am an electronics engineer not a car expert so don't take what I say as gospel,but the solenoid seems to close by some sort of switch possible two contacts making on the carburetor when the throttle is closed cutting off the fuel supply,so if you were to unplug the fuel cut off solenoid and connect the 2 wires (Single live wire - grounds out on carb body)of the solenoid valve directly to the car battery this will keep the solenoid open when when decelerating ,you could try this,it would prove the point rather than cutting off the plunger as there is no turning back when you have done this .

Not quite, it's ignition switched and the solenoid is supposed to be open as long as the car is running, it just drops the rod into the idle jet when the ignition is turned off to cut the fuel supply and stop the engine running on. All things working as they should snipping the plunger should make no difference as without a spark the engine stops just fine anyway. Connecting the solenoid straight to the battery is a pretty good plan as it's more reversible than snipping, but you'd then still need to figure out if it was the solenoid itself sticking closed or the wiring to it playing up.

Actually what you could do is disconnect the wire to it and fire the engine up (you'll need to give it throttle to make it run) and see if the symptoms match what you've been experiencing. It's a single wire that plugs onto a blade connector on the front of the base of the carb - it's the only electrical connector on there, can't miss it, dead easy.

Here we go, you can just see it here, the black connector immediately below where the fuel hose connects, black sheathed cable coming in from left of pic:

Last edited:

Actually a better idea , start the engine and unplug the single solenoid wire and the engine should cut out ,

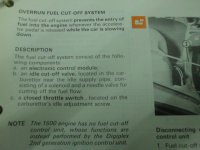

now I am at work and I have the main dealer service manual to hand its a bit more complicated than just a switch and solenoid, the solenoid is controlled by an electronic module connected to ignition coil to detect the RPM and a throttle closed switch on the carb, as the solenoid is spring loaded any loss of power to it will fire it into carburetor to cut the fuel off.

now I am at work and I have the main dealer service manual to hand its a bit more complicated than just a switch and solenoid, the solenoid is controlled by an electronic module connected to ignition coil to detect the RPM and a throttle closed switch on the carb, as the solenoid is spring loaded any loss of power to it will fire it into carburetor to cut the fuel off.

Attachments

Main dealer service manual for what? Can't help noticing a reference to a 1600 engine there so can't be a Panda. There's no switch on the idle adjust screw here for electronic jiggery pokery, It's just a straight ignition live as far as I know on this setup.

I was working on a less "scientific" approach with the suggestion of running the engine with the solenoid disconnected, more so the OP could get an idea if the symptoms feel the same as when the issue comes up on the road.

I was working on a less "scientific" approach with the suggestion of running the engine with the solenoid disconnected, more so the OP could get an idea if the symptoms feel the same as when the issue comes up on the road.

Main dealer service manual for what? Can't help noticing a reference to a 1600 engine there so can't be a Panda. There's no switch on the idle adjust screw here for electronic jiggery pokery, It's just a straight ignition live as far as I know on this setup.

I was working on a less "scientific" approach with the suggestion of running the engine with the solenoid disconnected, more so the OP could get an idea if the symptoms feel the same as when the issue comes up on the road.

To explain how the fuel cut off solenoid operates on the fiat Tipo

It was you who suggested in a post 3 days ago the fuel cut off solenoid could be sticking,I have no idea if the panda uses this set up or not,I was simply telling my experience on my Tipo which has now been running fine for the last 20 years with the plunger sawn off.

That's what I thought. I wasn't trying to pick fault or anything, just on the Panda, unlike the Tipo system obviously, the solenoid isn't constantly cutting in and out as you drive, it's just engaged with the ignition off and out when the engine is running. From a diagnosis point of view that's going to produce quite different symptoms if something goes wrong.

According to my Haynes manual, the cut-off solenoid is fed directly from the ignition switch.

The plunger is spring loaded, so will close when the power is cut. If it is cutting the fuel supply before the ignition is switched off, then either, the solenoid is dying, or the feed from the ignition switch is disconnecting.

As described above, with engine idling, disconnect the wire. See if this matches the symptoms.

If the ignition switch is worn, it may be disconnecting the supply. Too many keys hanging in the lock can wear the switch quite quickly. When the engine cuts out, the supply to this solenoid needs to be tested, with a test lamp, or multimeter.

Of course, if the ignition switch is faulty, it might just be cutting the supply to the coils, and the carburettor is not the problem. However, the other running problems described point to a rich mixture, so the service kit is still a good idea.

The plunger is spring loaded, so will close when the power is cut. If it is cutting the fuel supply before the ignition is switched off, then either, the solenoid is dying, or the feed from the ignition switch is disconnecting.

As described above, with engine idling, disconnect the wire. See if this matches the symptoms.

If the ignition switch is worn, it may be disconnecting the supply. Too many keys hanging in the lock can wear the switch quite quickly. When the engine cuts out, the supply to this solenoid needs to be tested, with a test lamp, or multimeter.

Of course, if the ignition switch is faulty, it might just be cutting the supply to the coils, and the carburettor is not the problem. However, the other running problems described point to a rich mixture, so the service kit is still a good idea.

Pandateria

New member

- Joined

- May 24, 2015

- Messages

- 32

- Points

- 11

Thanks for this. Will check it out. Just wondering though - I fill the tank with either Super Unleaded, or Shell Ultra V because I was told they were better for the engine. Is the petrol I use right for the car, or is it causing a problem?

lukmek

Established member

- Joined

- Mar 12, 2012

- Messages

- 1,653

- Points

- 463

Thanks for this. Will check it out. Just wondering though - I fill the tank with either Super Unleaded, or Shell Ultra V because I was told they were better for the engine. Is the petrol I use right for the car, or is it causing a problem?

I would not use the "super petrol" kind on the engine either

I do think may have beneficial proprieties in modern engine

In my opinion that's not the case in a Panda engine

Thanks for this. Will check it out. Just wondering though - I fill the tank with either Super Unleaded, or Shell Ultra V because I was told they were better for the engine. Is the petrol I use right for the car, or is it causing a problem?

As the Panda engine is a lowly stressed engine, you are just wasting your money. You may get slightly improved economy, but not enough to pay the cost difference.

However, the other running problems described point to a rich mixture, so the service kit is still a good idea.

Although that can be caused by some garage with no experience of carbs "tweaking" every so often..

Of course, if the ignition switch is faulty, it might just be cutting the supply to the coils, and the carburettor is not the problem.

Engine would not run at all then though, wouldn't be linked to closed throttle only.

Not really, all they can tweak is the slow running mixture, which will have little effect once the throttle is opened. Then it is all down to jet sizes, air leaks, and float height.Although that can be caused by some garage with no experience of carbs "tweaking" every so often..

True, its been a long time since the original post.Engine would not run at all then though, wouldn't be linked to closed throttle only.

Not really, all they can tweak is the slow running mixture, which will have little effect once the throttle is opened. Then it is all down to jet sizes, air leaks, and float height.

True in theory, that's why I'd be worried what a garage might be "tweaking" on the carb every few months. If it's gone in with the symptoms described originally then just twiddling with the idle mix and idle speed screw wouldn't have any noticable effect so would be interesting to know what the garage actually has done to it to diagnose it's knackered and a replacement is needed. Cleaning out all the accessible jets with a pokey implement maybe? To be fair it's only flooding with the choke out so that's easily cured by just not pulling the choke out. Shouldn't need it for more than a few minutes anyway, and probably not at all if coming back to the car before it has cooled down as described.

Not needing much choke, and difficult to start when warm, prone to stalling when warm, suggest running rich. Hence my thoughts on float height.

Garage don't understand the effect of their tweaks, and as this has not fixed it, they have recommended replace the carb.

Garage don't understand the effect of their tweaks, and as this has not fixed it, they have recommended replace the carb.

Similar threads

- Replies

- 0

- Views

- 247

- Replies

- 8

- Views

- 475