As i've read on here a few times, "Pandas really do multiply" Edinburgh zoo should do a study.

Just had my new 1995 CLX arrive on the drive as proof, courtesy of Velocemitch.

It has an engine, it has doors, wheels and a steering wheel so im very happy!!!

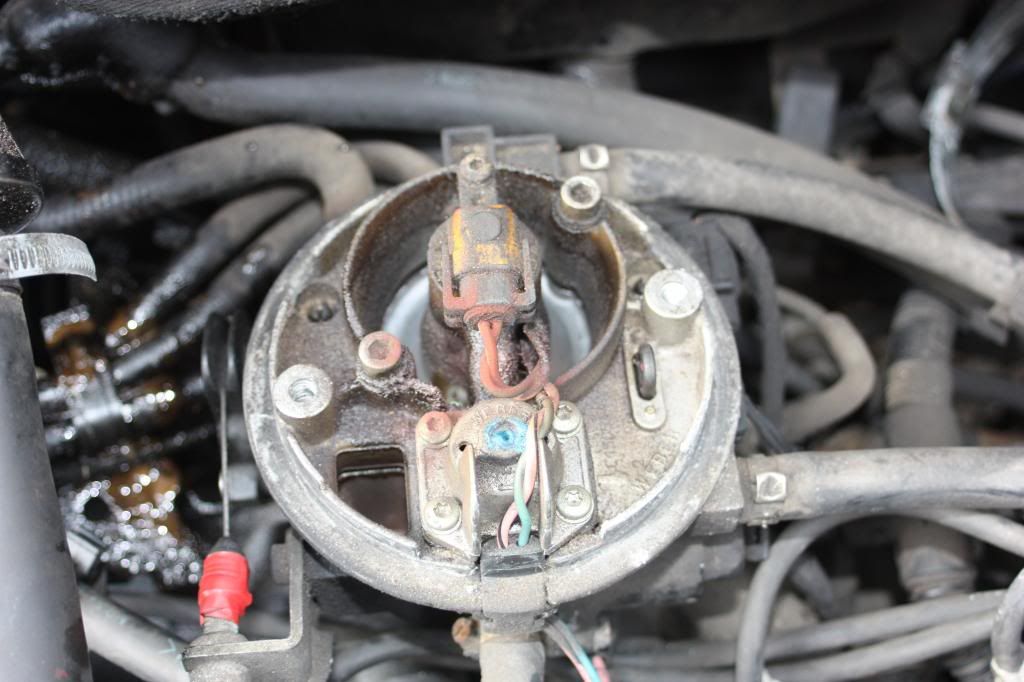

Major points are head gasket needs replacing,

Both rear seatbelt mounts need welding

Sills need welding

Rear gearbox mount needs re-attaching

Im not the most technical speaking of guys, and i do call things in lamens terms.

Im planning on doing everything to this car myself as a project...bare in mind iv only ever worked on classic japanese motorcycles, I've never welded, iv never worked with a 4 stroke engine before, pretty much apart from drive a car iv done nothing.

Im sure some of you may be doubting what will happen as we crack on with this, and im sure ill make a lot of mistakes and spend a lot of money,

Im looking forward to it.:slayer:

Just had my new 1995 CLX arrive on the drive as proof, courtesy of Velocemitch.

It has an engine, it has doors, wheels and a steering wheel so im very happy!!!

Major points are head gasket needs replacing,

Both rear seatbelt mounts need welding

Sills need welding

Rear gearbox mount needs re-attaching

Im not the most technical speaking of guys, and i do call things in lamens terms.

Im planning on doing everything to this car myself as a project...bare in mind iv only ever worked on classic japanese motorcycles, I've never welded, iv never worked with a 4 stroke engine before, pretty much apart from drive a car iv done nothing.

Im sure some of you may be doubting what will happen as we crack on with this, and im sure ill make a lot of mistakes and spend a lot of money,

Im looking forward to it.:slayer: