Spent Today ordering vital parts for the project (hard to believe it took all day nearly):

Matching LUK DMF and Clutch Kit: for Multipla 1.9 JTD 110 2001 Reg. from

www.buypartsby.co.uk:

LUK DMF PN: 415039310 (£161)

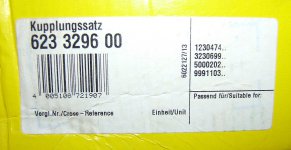

LUK Clutch Kit PN: 623329600 (£77)

The engine code is needed to be sure of ordering the right parts. I found the engine code printed on the

model plate fixed at the back of the engine bay under the bonnet lip: 186A6.

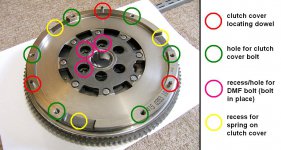

DMF bolts: I rang LUK UK (T. 01432 264264) to obtain the part no. for the matching LUK DMF bolts (PN: 411012210). Very helpful technical guy at LUK. I remembered to ask for the DMF and clutch cover bolt torque settings: 136 Nm and 25-30 Nm. He wasn't certain about the clutch cover bolt setting, so I'll double check at the Fiat main dealer tomorrow.

He also explained that matching the bolts to the DMF is important because DMF specification (thickness in this case) varies by model and manufacturer, so the bolts vary in length accordingly, he said.

To order the bolts, I went the long way round first (trawling the Internet, didn't like the prices or uncertain delivery times) before discovering the short way: rang my local partstealer who said £5 + VAT, will have them in first thing tomoz. Result !

Fiat Multipla car jack: (Reminder: I'm going to use two) I think the Fiat main dealer quoted me £58-ish for a new Fiat car jack. I ordered a used one Today on Ebay for £22 including delivery. When I mentioned this to my local partstealer he made a very valid point: a secondhand jack will probably be in good condition because they're rarely used - how often do people get a puncture and have to change a wheel... Anyway Result No. 2 !

To finish the day I went along to my local partstealer to check whether my other bits and bobs had arrived. He tried to fob me off with 2 non-matching drop-links from 2 different manufacturers. Bit of a giveaway really - one was painted black, the other silver, so obvious even to me. I said no thanks, I'll have two the same if it's alright with you...

Gearbox oil: Came home with some vindscreen vipers (that's German for ...) and 2L of gearbox oil. He gave me Comma 75W-90 GL-5, the manual says 75W-80. Wonder if it'll make much difference? Anyway it was cheap at £5 a litre, so I could always run around with it for a while to flush the gearbox, and replace with some good stuff at a later date... What say you?

(Aside: My research tells me that the first number "75W" in the oil spec is the viscosity when cold (W = Winter), and the second number I ain't sure about, it can't be viscosity when warm cos' oil gets thinner as it heats up, or...? Anyway I discovered that there are heated arguments going on on t'Internet about the virtues of 75W-80 versus 75W-90 culminating in dueling matches with pistols at dawn. Presumably after a long previous day trainspotting... You'll never believe this, but the other day I actually saw a man

bus-spotting at my local bus station! Just when you think the human species can't stoop any lower...)

That's all for Today. Off to the Fiat main dealer tomorrow (well Today now, it's gone midnight) for driveshaft seals and clutch fork sleeves. Perhaps I'll have a sneaky peek at a bus number plate on the way to add to the excitement...

Mark X