Introduction

So, I've been after a 4x4 for using on the rough stuff for a while, and today I've finally got one

Let me introduce Digger:

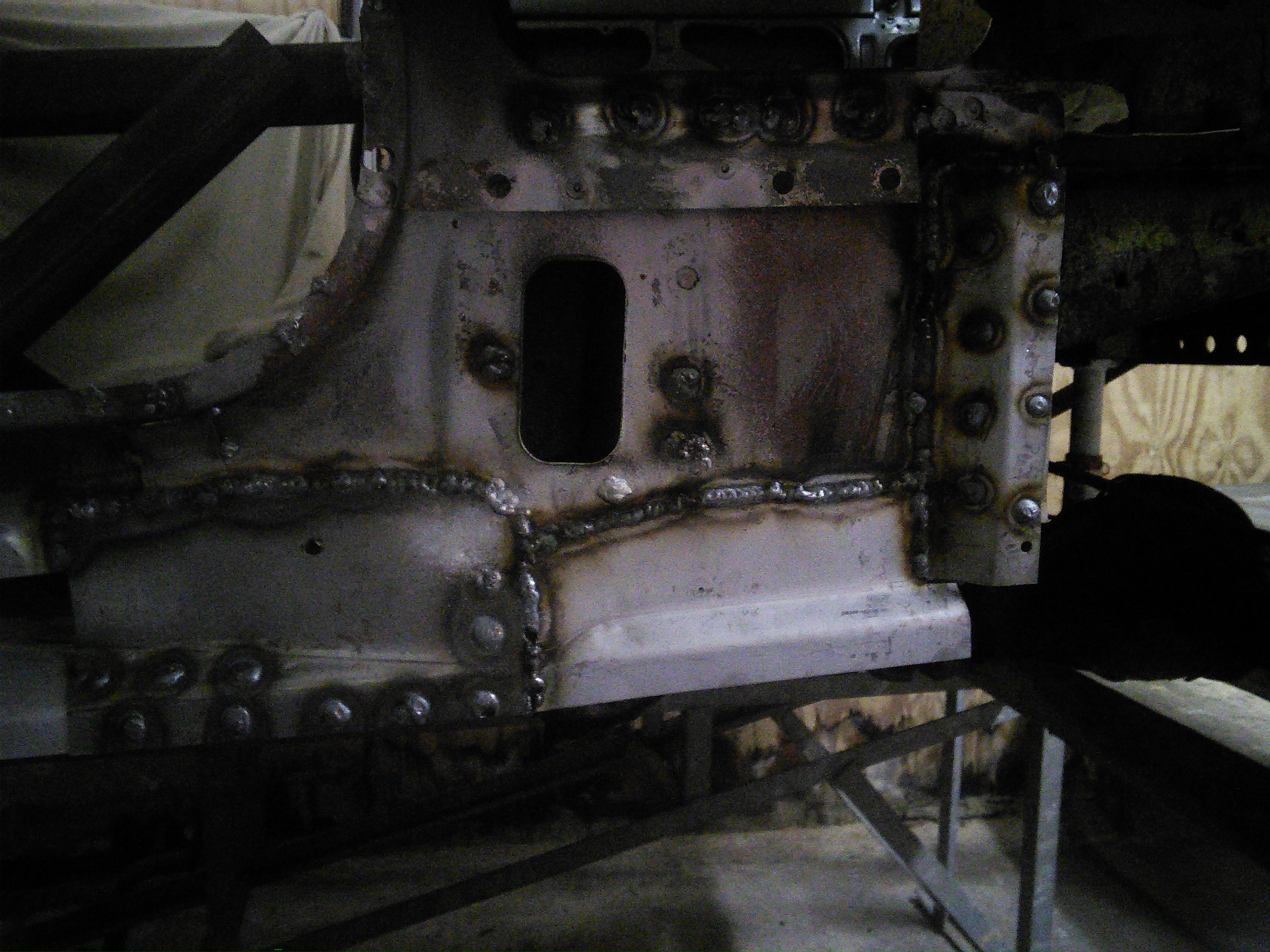

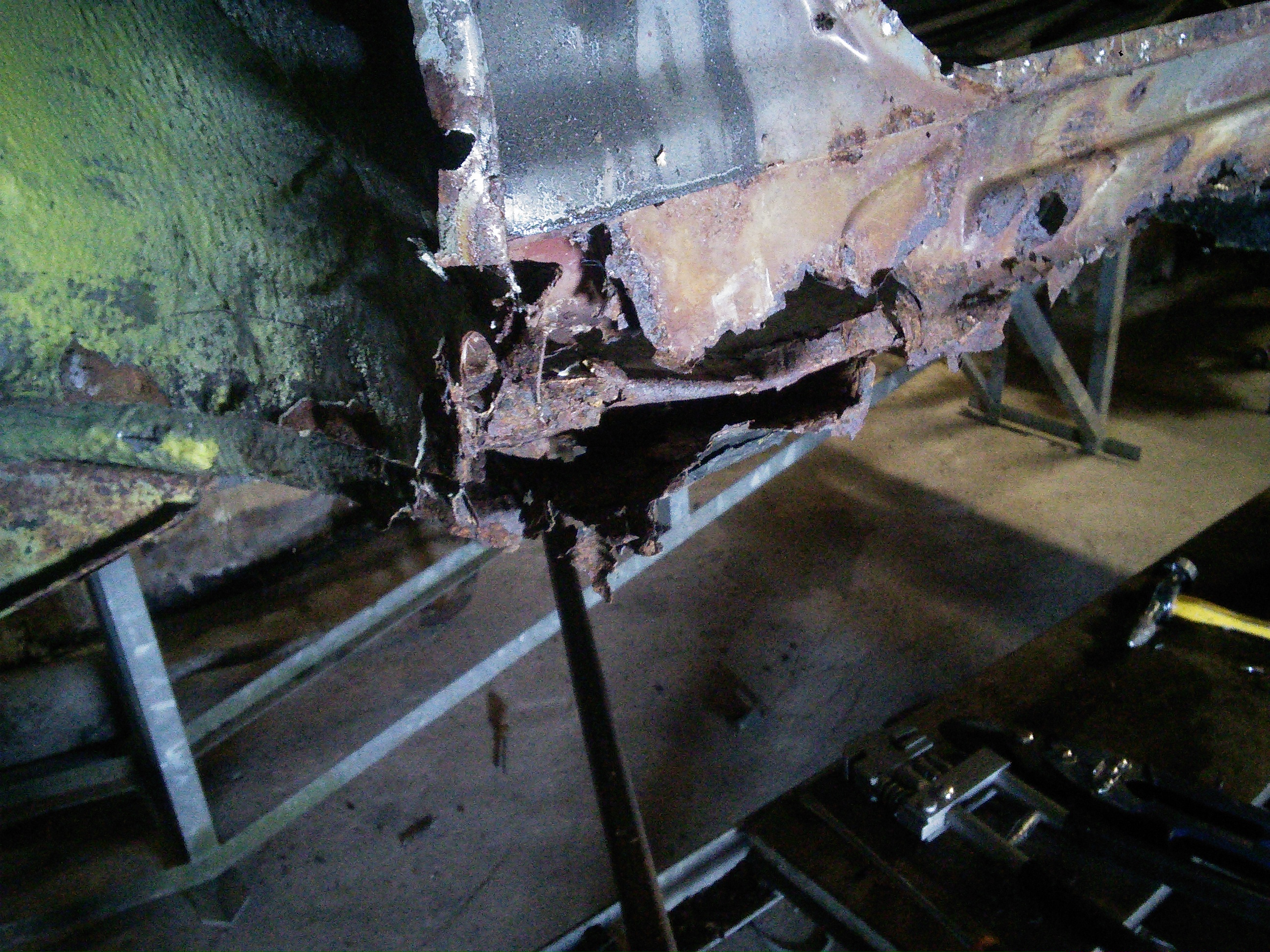

Named by my Dad due to his JCB yellow paint job! He's been off the road for 12 years in dry storage and as to be expected he needs all the usual Panda stuff attending to, the biggest problem being rust of course! Mechanically, he has faired well, and should just need a recommissioning rather than any major surgery.

After going to see it last weekend, I was outbid in the last few seconds of the eBay auction, lucky for me, (not so the for the seller) the winning bidder was a complete time waster so I got a second chance offer and arranged collection for today. As usual my Land Rover was on towing duty:

Good job the 4wd on Digger works as I needed it to get onto the trailer! Anyway we dropped him off at my workshop (actually the corner of my Dads warehouse ) and tomorrow I'll give him a good clean (including evicting the many spiders living in the engine bay) and a proper look over.

) and tomorrow I'll give him a good clean (including evicting the many spiders living in the engine bay) and a proper look over.

I'd like to get him back on the road fairly quickly, in time for AndyPanda4x4's next Yorkshire weekend And then a few mods to improve his off road ability will be on the cards I think.

And then a few mods to improve his off road ability will be on the cards I think.

Let me introduce Digger:

Named by my Dad due to his JCB yellow paint job! He's been off the road for 12 years in dry storage and as to be expected he needs all the usual Panda stuff attending to, the biggest problem being rust of course! Mechanically, he has faired well, and should just need a recommissioning rather than any major surgery.

After going to see it last weekend, I was outbid in the last few seconds of the eBay auction, lucky for me, (not so the for the seller) the winning bidder was a complete time waster so I got a second chance offer and arranged collection for today. As usual my Land Rover was on towing duty:

Good job the 4wd on Digger works as I needed it to get onto the trailer! Anyway we dropped him off at my workshop (actually the corner of my Dads warehouse

I'd like to get him back on the road fairly quickly, in time for AndyPanda4x4's next Yorkshire weekend