Introduction

Here is the latest addition:

Well what else can you expect from a free gearbox

Seriously though, on my head it was a fantastic gearbox for as long as I ran it, oil was regularly changed (self service) and there was never any worrying noises.

Nice job, Sir! I am watching with keen eyes how things get together eventually!

I will be really happy to hear about a test ride.

Only thing I can't get round is that the starter motor will be bolted to the adaptor plate and the fixings will be behind the gearbox bell housing...so irritatingly when I replace the starter motor I will have to split engine / gearbox!! Therefore a very much new starter motor will be going on haha!

Exciting times

Wow is that my old gearbox?!

Damn if only I'd have done that before then I could have charged you more than nothing!

Seriously though good work Si, I hope you can continue the efficient progression!

It was 5 hours + of cleaning so you might've done the right thing lol...seemed a shame almost to remove the history though...I am quite familiar with Italian, Yorkshire mud types now :devil:

Hadrian will live on! :slayer:

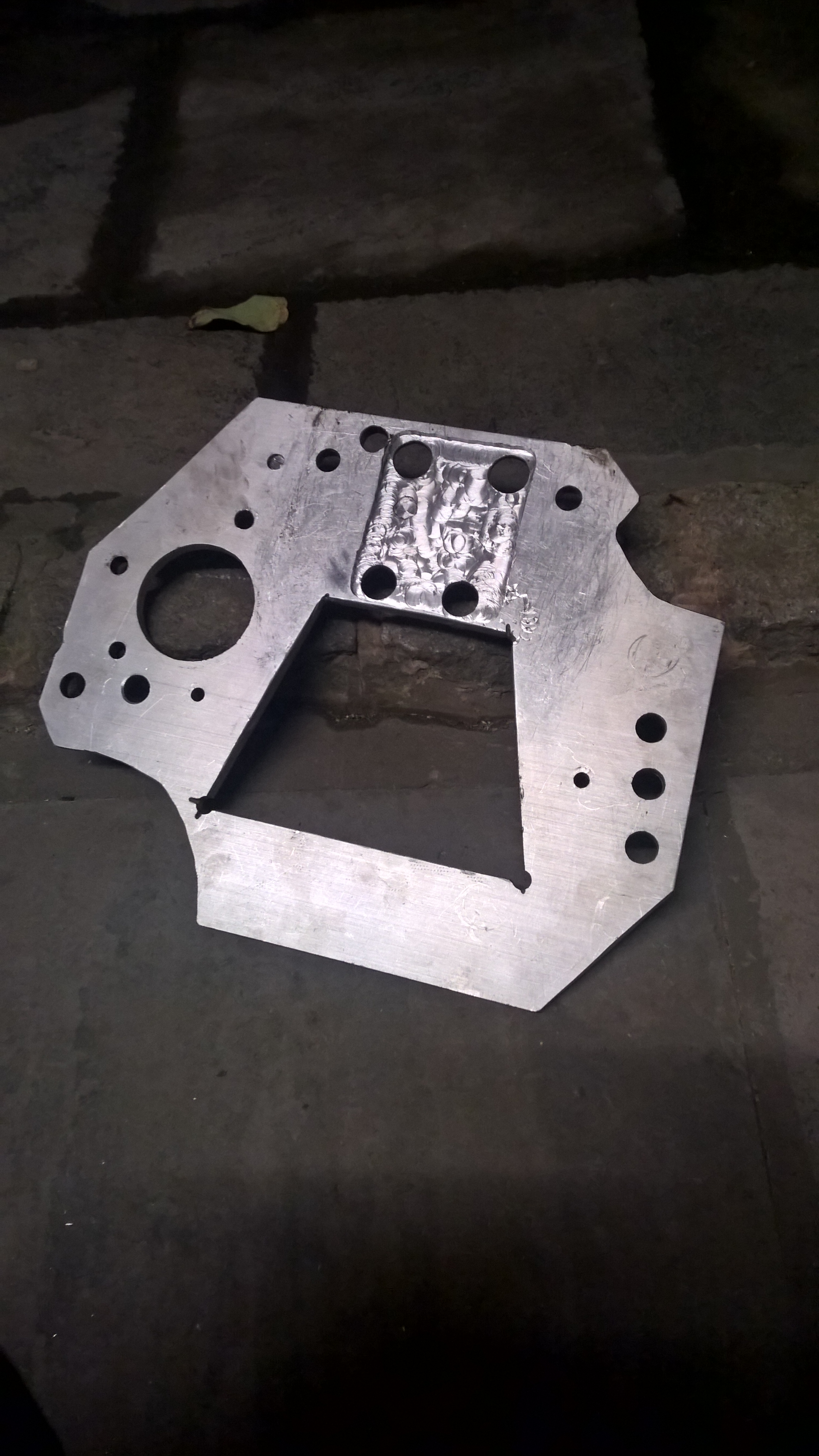

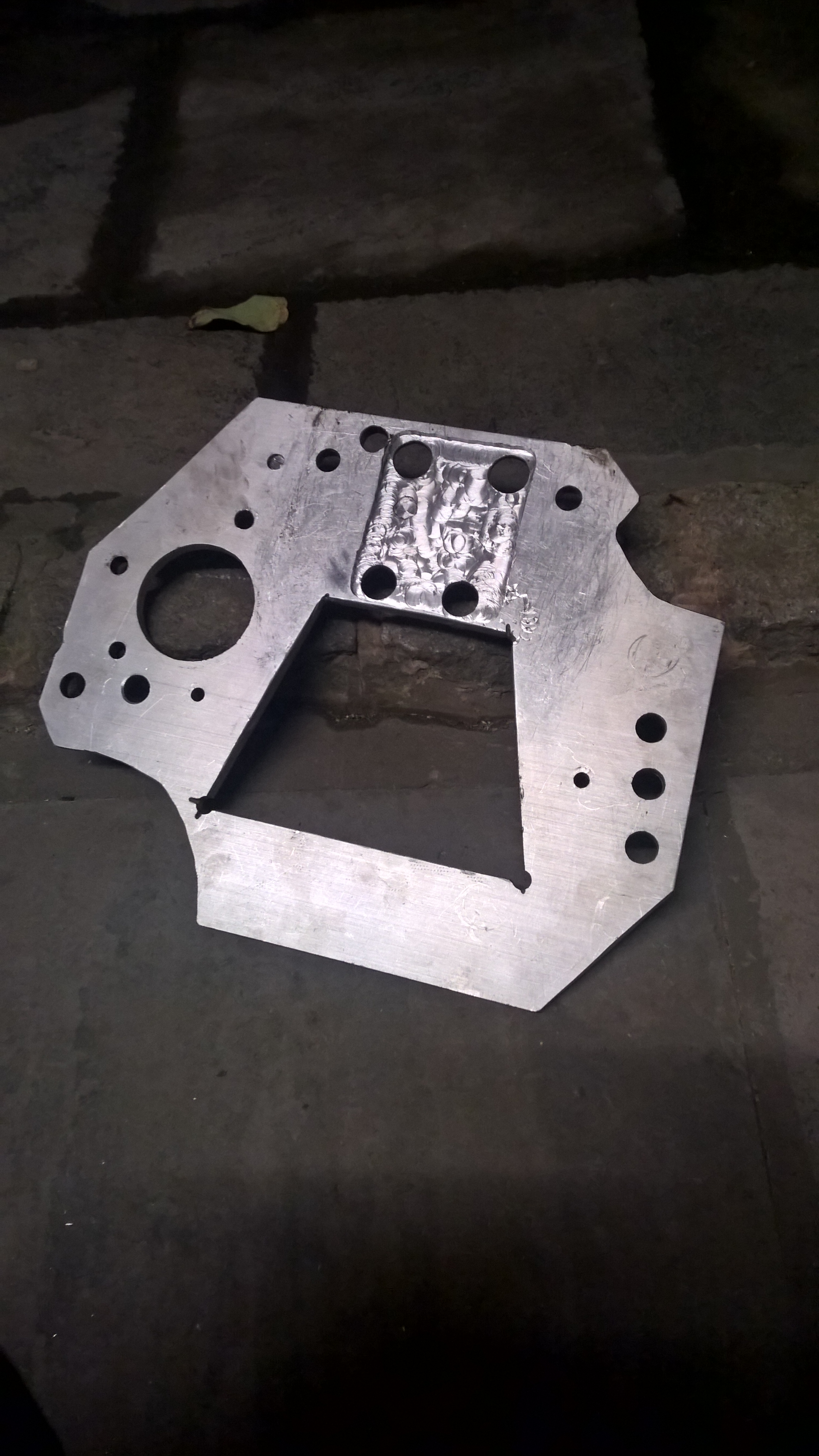

The answer to the question can a router be used for milling a recess into aluminium plate...is yes! I did go through a few bits but really once had got the knack of it they broke less frequently:

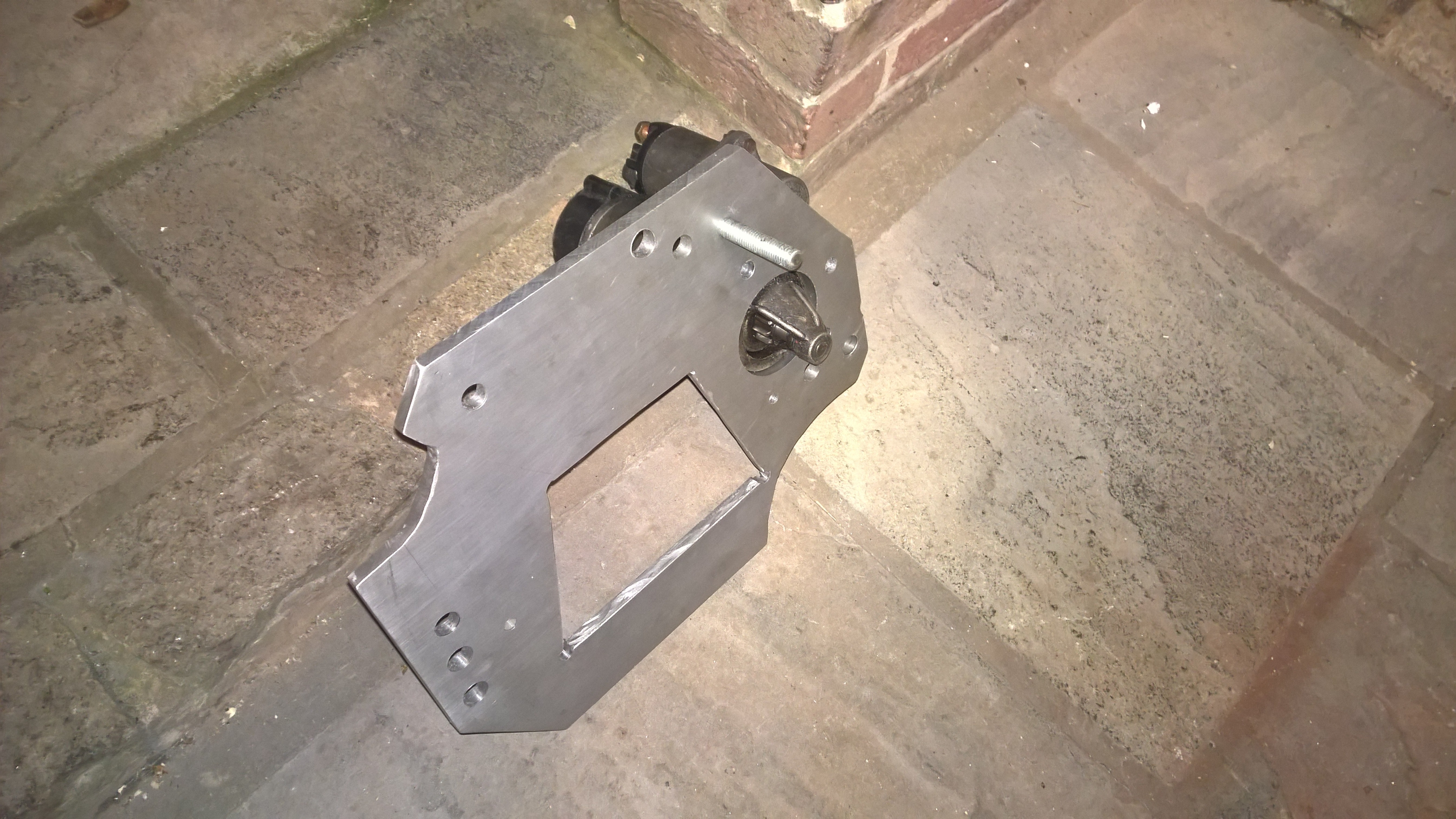

So now fits nicely onto the block and starter motor seems to be in the correct position (fingers crossed!):

..although discovered a new issue. The oil sump is actually stopping the plate from sitting flat on the block...so I've got some more cutting to do it seems!

Getting there though

Si

On topic but sideways slightly :

Is the intention to drive in full 4x4 at all times ?

If so is the intention to insert a fluid coupling in the drive to try to eliminate wind up or is there another plan ?

What are your thoughts ?

As our projects an off roader with an increase in power and increase in wheel rolling diameter so 20% torque increase wheel and 40% power

We think a heavier fly wheel may help shock loads and be better for crawling plus the addition of a fluid viscous coupling will also help

Regards

Steve

Sorry came into this thread late

Rear wheel drive conversion

Ah I see yes great idea

Sorry again