CallumColes

New member

- Joined

- Feb 13, 2017

- Messages

- 19

- Points

- 3

Sorry for my terribly poor English understanding, what does mean incafitant ? Google translate doesn't give me any result :-(

Regards, Bernie

Sorry my bad cant spell lol insufficient

Sorry for my terribly poor English understanding, what does mean incafitant ? Google translate doesn't give me any result :-(

Regards, Bernie

Hi,

that's much clear like this ;-) My understanding of the Dual-logic transmission is that the clutch is actuated by a cylinder the same way as a manual gearbox is (please someone corrects me if I'm wrong).

Can you see any bleeder on that clutch cylinder assembly ? Air in the system could be the cause of insufficient stroke ...

Regards, Bernie

I also have the same car as this with what looks to be the same problem.

whilst messing with it I have discovered that i can get the car to go into gear by pushing in the clutch leaver assembly on the gearbox robot by hand when the engine is off, the only problem is i have to do this to get it back into neural.

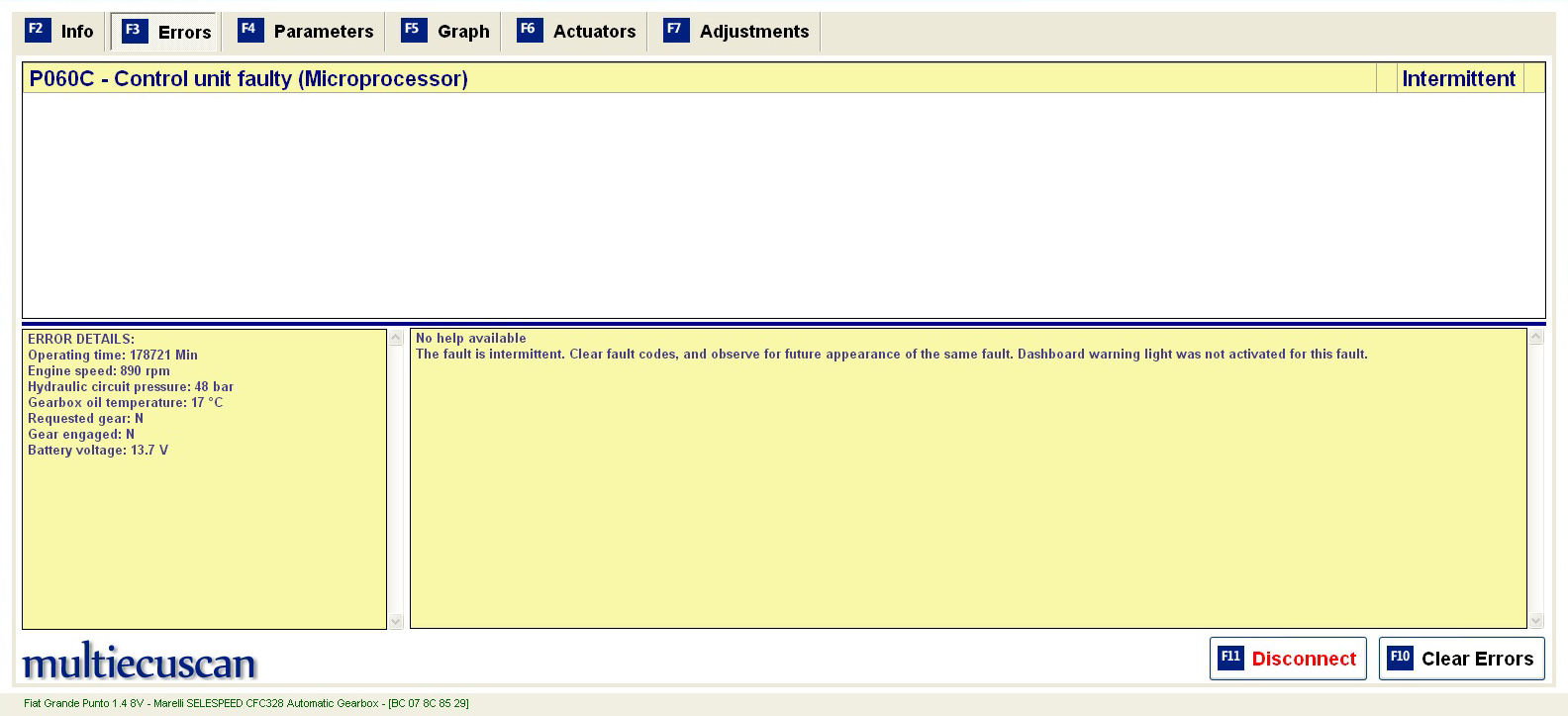

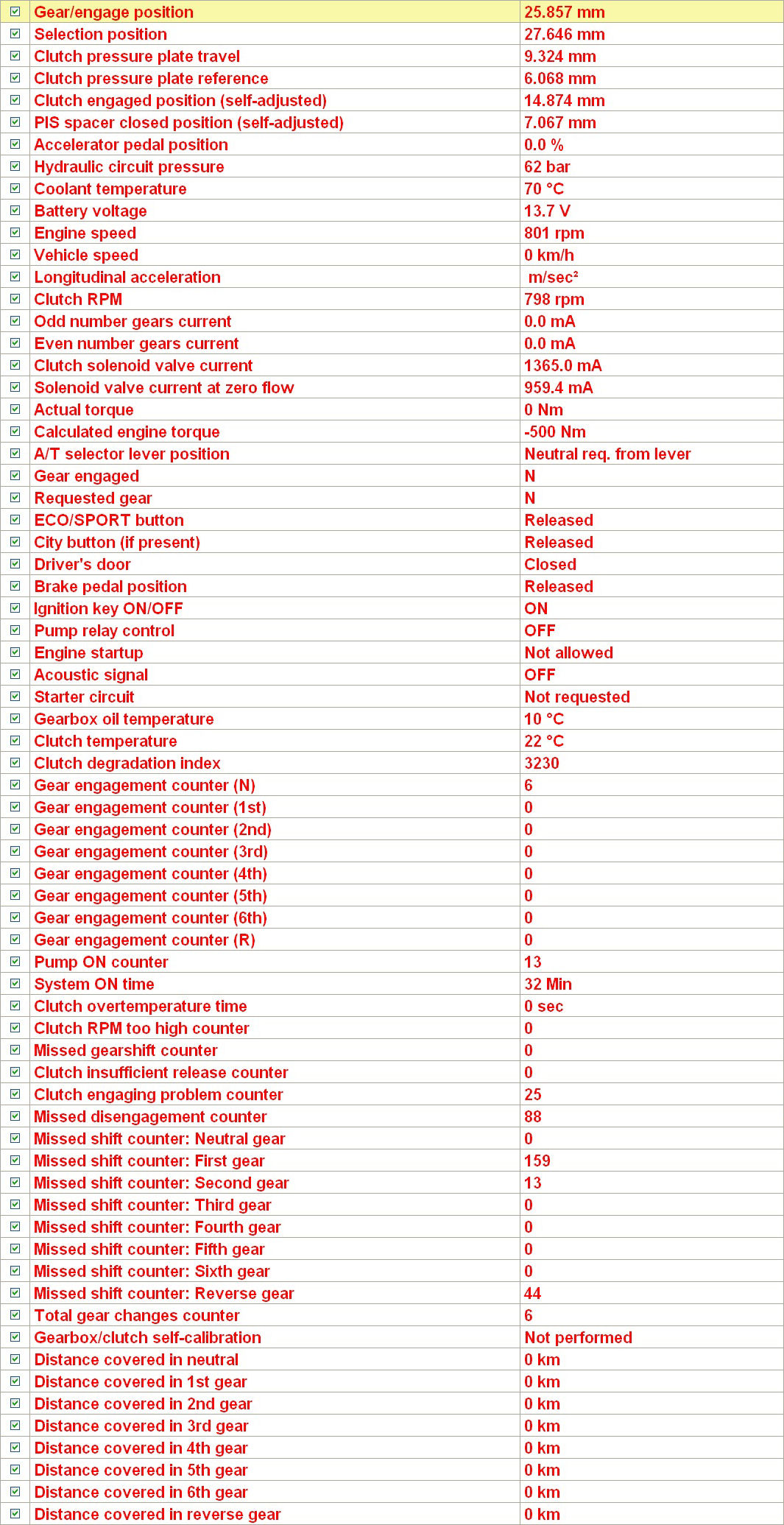

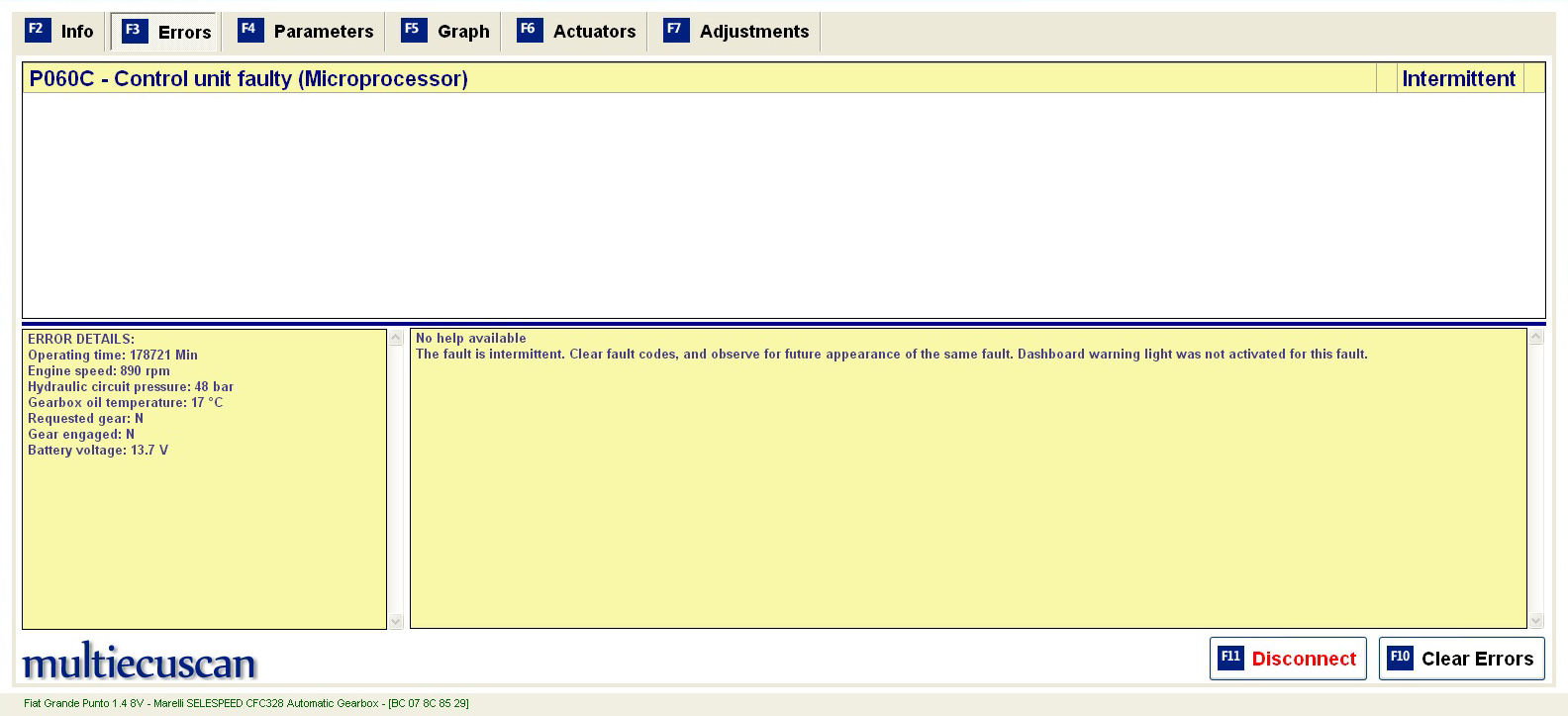

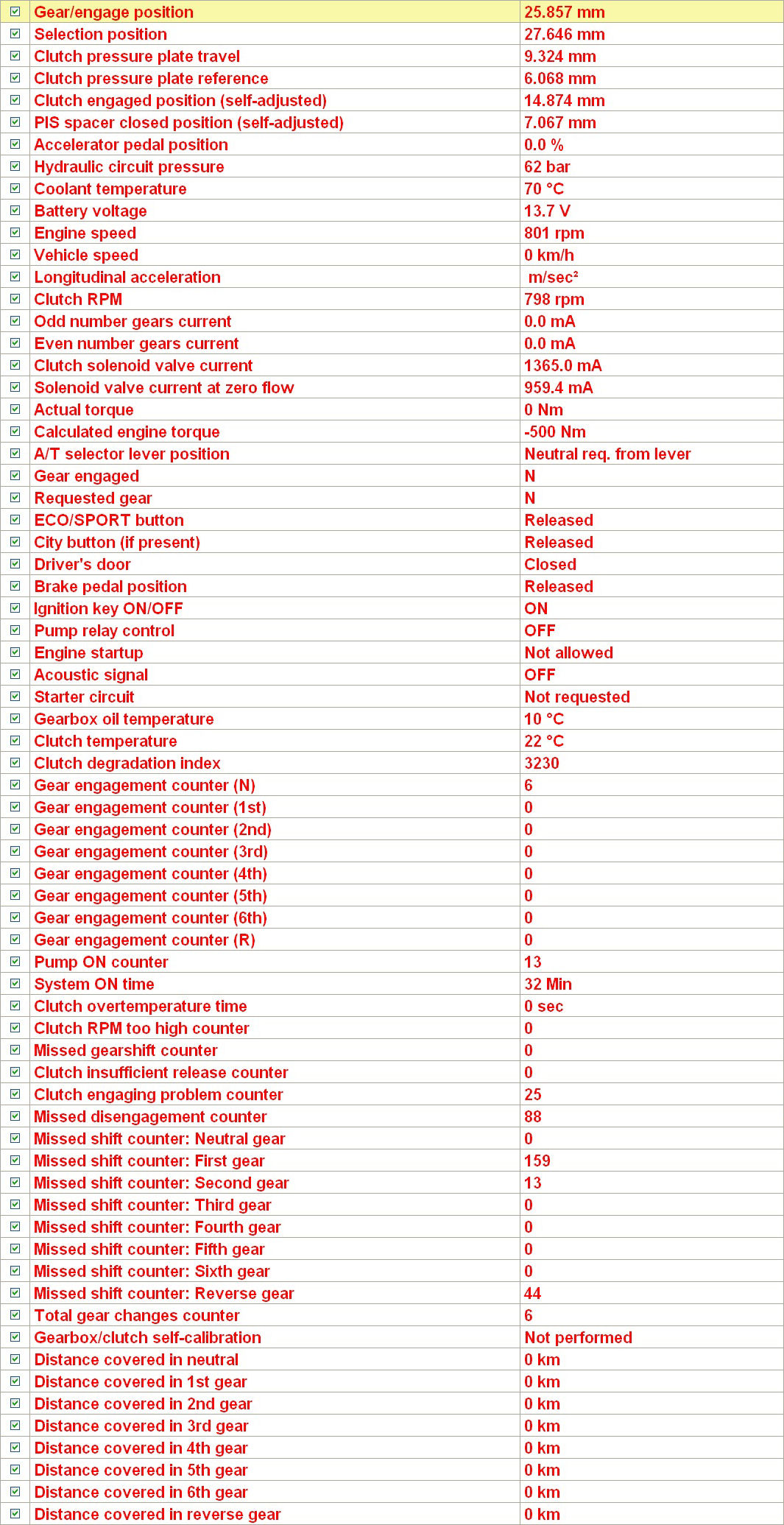

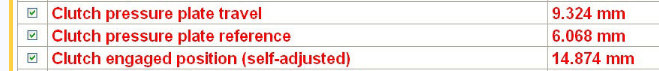

Attached are the details from my ecu, i can see that there are a number of differences but not sure what really to look for? also yours are from a static engine, i took mine while it was running.

Also when i run the production service calibration i get the following error '5th - 6th sel failed'

The way the clutch is actuated depends of the robot and gearbox.

For the 6 speed M20 gearbox the robot is the CFC300 in this system

The Master-Slave system hydraulic fluid pushes a piston which then push DOT4 brake fluid which in turn pushes the CSC (Clutch slave cylinder) actuator inside the clutch housing. The clutch position sensor is incorporated into the Master-Slave system

For the 5 speed C514 gearbox the robot is the CFC328.

Hydraulic fluid pushes the CSC (Clutch slave cylinder) actuator directly.

I dont know about the CFC328 but for the CFC300 there is a bleed valve on the Master-Slave system.´

The only way to be certain of what is causing the issue would be to inspect the clutch.

Hi Callum,

as Auricks suggested, the clutch potentiometer signal can be wrong, i.e telling teh ECU the clutch is not disengaged while it actually is, so the ECU would NOT allow the gear engagement...

Have a look here:

http://www.alfa147selespeed.co.za/tips_guides/how-to-test-your-sensors-potentiometer/

It's for a 147 selespeed but you get the idea...

Regards, Bernie

I have found the following online which supports that the pressure is to high, however i have also found information that suggests that the system has a recovery mode and when this is active the running pressure is increased beyond normal parameters. Also when the error was first captured the pressure was only at 48psi which from what i have read is the optimal pressure.I dont know if this is valid for the CFC328 robot but for the CFC300 when you install the pot you are supposed to preload it.

JFerris321 also your hydraulic pressure seems very high. 62bar

"The pump is activated when the accumulated pressure drops under 40 bars and is stopped (off) when the accumulated pressure is 50 bars"

I have found the following online which supports that the pressure is to high, however i have also found information that suggests that the system has a recovery mode and when this is active the running pressure is increased beyond normal parameters. Also when the error was first captured the pressure was only at 48psi which from what i have read is the optimal pressure.

"

CFC328 fitted to the C514 gearbox (500, Panda, Grande Punto)

• Working hydraulic pressure from 41 to 51 bars

• Operating temperature from -30˚C to + 125 ˚C

• Cranking is must be possible also at -30°C

• The pump flow rate is 0.8 l/min at 60°C

• The accumulator volume is 280 cm³ preloaded at 27 bar at 25°C

Accumulator is fitted to solenoid valve unit.

"

In regards to preloading the pots, there is only one way they will go on and this requires you to do very much the same as what is shown in your attached document so i am pretty sure they are on correctly.

Thanks for posting the result of your investigations !

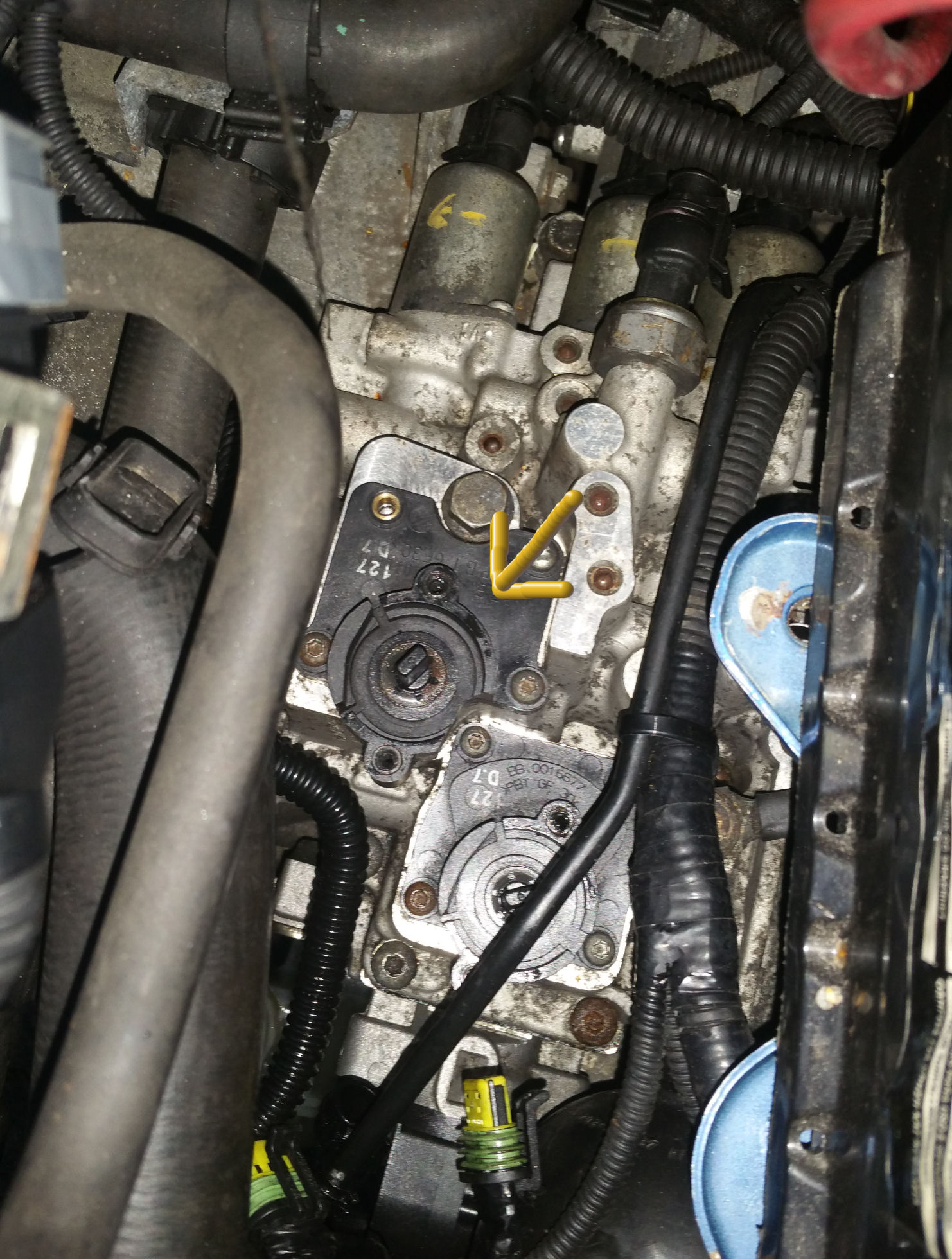

Next question is WHY and HOW this arm did bend !?

Regards, Bernie

Hi All,

Just to update replacing the clutch, clutch release arm and bushes the car now drives sweet and has only cost me £120 all in