If you're doing a clutch on a sporting then you'll find the centreplate splines are quite small. My universal tool wouldn't fit.

If you dont get the centreplate central then you're box aint never going back in. Don't bother doing it by eye. I was trying to find something but couldn't find that perfect fit. Then my dad appears with a bit of standard copper water pipe. PERFECT! Fits in flywheel tight. So there you go lads!!

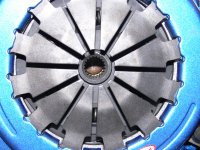

And I tell you what, the clutch fingers on mine were virtually through. One had pinged off. Thats why I was getting a cracking sound and I drepressed pedal. My new original valeo clutch is about 10 times lighter and so smooth. So I reckon that's why these cables break. A knackered old stiff cover causes drag which overloads your cable and mech.

Don't waste your time buying cables. For £40 spend about 3 hours grafting and put in a valeo!! Quite a nice job if you take your time.

Over and out

If you dont get the centreplate central then you're box aint never going back in. Don't bother doing it by eye. I was trying to find something but couldn't find that perfect fit. Then my dad appears with a bit of standard copper water pipe. PERFECT! Fits in flywheel tight. So there you go lads!!

And I tell you what, the clutch fingers on mine were virtually through. One had pinged off. Thats why I was getting a cracking sound and I drepressed pedal. My new original valeo clutch is about 10 times lighter and so smooth. So I reckon that's why these cables break. A knackered old stiff cover causes drag which overloads your cable and mech.

Don't waste your time buying cables. For £40 spend about 3 hours grafting and put in a valeo!! Quite a nice job if you take your time.

Over and out