Times change.

So, we are entering a new era of Fiat engines. The euro 4/5 or what ever they are called now.

Any one wanting to do an engine change for a low mileage one from the new range, Beware!

Fiat have been busy with thier unification programme. This is to try and standardise many parts within the new engine range.

The new type cylinder head from the 8v has a new basic camshaft design, so no more 866 cam fitting.

The top one is the new type.

The New Panda 1.1 came with a 673 cam with about a 7.5+mm lift.

The 1.2 Grande Punto came with a 804 cam with about 9.5+mm lift.

I don't know any of the other specs.

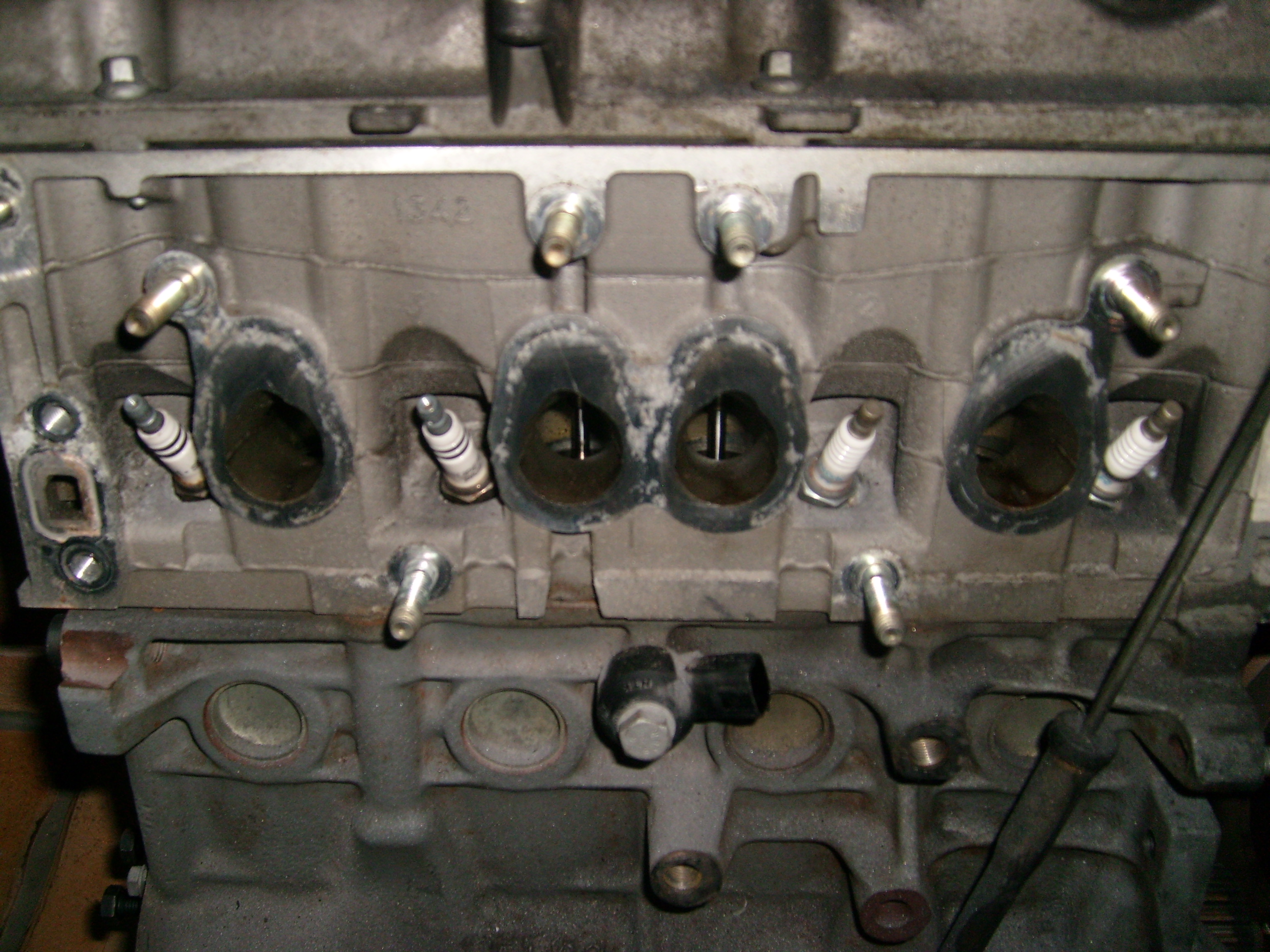

The inlet ports on the 1.1 are not the same as the 1.2, which used to be on the earlier MPI heads.

1108 inlet ports.

1242 inlet ports.

New head internal design.

The 1242 came with a metal type head gasket but the 1108 did not.

The 1242 also may not have the cut out in the head for the inlet manifold water temp sensor as fitted to the 1108. This will be evident with the new style multi outlet thermostat housing.

1242. The castings on this head could be based on the old punto 75 mpi head?

1108. You can see the multi process casting lines alot on this head.

Cam cover with new style intergrated oil feeds for the cam bearings.

The crank shaft diameter is bigger on the crank pulley end. This has a new crank pulley which is wider and uses a wider belt/new water pump/cam pulley and spring loaded tensioner bearing design.

Siecento MPI alternator fitted here.

The normal alignment problems.

I believe I have one solution to the above problem. The 2005 seicento has an oil pump with the same seal part No; as the 1242 with the larger crank. I have ordered one from Poland complete with new drive gear, which at present, comes to £126 for a complete pump. Fiat part No: 55205333, and Fiat part No: 55205336 for the drive gear @ £17. I have also ordered the alternator drive pulley 55181185 to match, as the holes have been shifted a few degrees.

So, we are entering a new era of Fiat engines. The euro 4/5 or what ever they are called now.

Any one wanting to do an engine change for a low mileage one from the new range, Beware!

Fiat have been busy with thier unification programme. This is to try and standardise many parts within the new engine range.

The new type cylinder head from the 8v has a new basic camshaft design, so no more 866 cam fitting.

The top one is the new type.

The New Panda 1.1 came with a 673 cam with about a 7.5+mm lift.

The 1.2 Grande Punto came with a 804 cam with about 9.5+mm lift.

I don't know any of the other specs.

The inlet ports on the 1.1 are not the same as the 1.2, which used to be on the earlier MPI heads.

1108 inlet ports.

1242 inlet ports.

New head internal design.

The 1242 came with a metal type head gasket but the 1108 did not.

The 1242 also may not have the cut out in the head for the inlet manifold water temp sensor as fitted to the 1108. This will be evident with the new style multi outlet thermostat housing.

1242. The castings on this head could be based on the old punto 75 mpi head?

1108. You can see the multi process casting lines alot on this head.

Cam cover with new style intergrated oil feeds for the cam bearings.

The crank shaft diameter is bigger on the crank pulley end. This has a new crank pulley which is wider and uses a wider belt/new water pump/cam pulley and spring loaded tensioner bearing design.

Siecento MPI alternator fitted here.

The normal alignment problems.

I believe I have one solution to the above problem. The 2005 seicento has an oil pump with the same seal part No; as the 1242 with the larger crank. I have ordered one from Poland complete with new drive gear, which at present, comes to £126 for a complete pump. Fiat part No: 55205333, and Fiat part No: 55205336 for the drive gear @ £17. I have also ordered the alternator drive pulley 55181185 to match, as the holes have been shifted a few degrees.

Last edited: