Just over a month ago, my 1242 8v MPI blew its head gasket. I had vowed not to change it again on that engine, so true to my word I did not.

So that came out;

looks odd this high off the ground

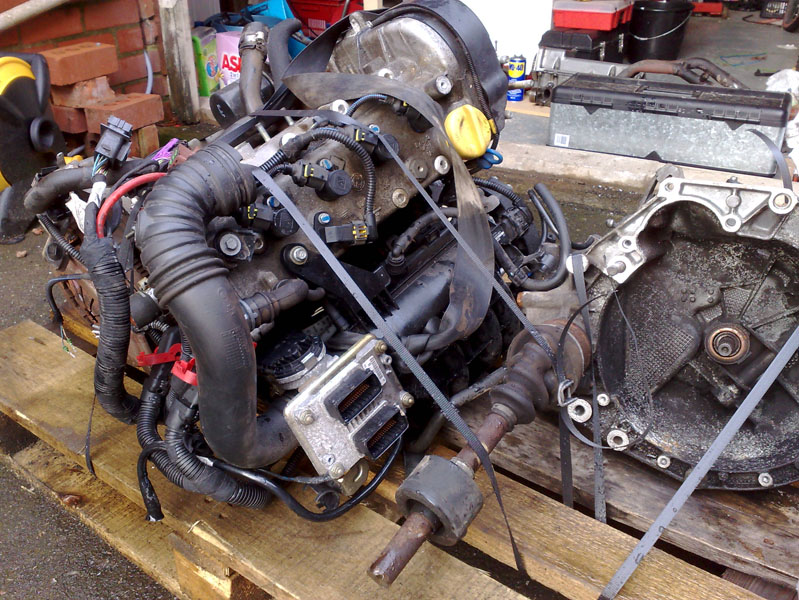

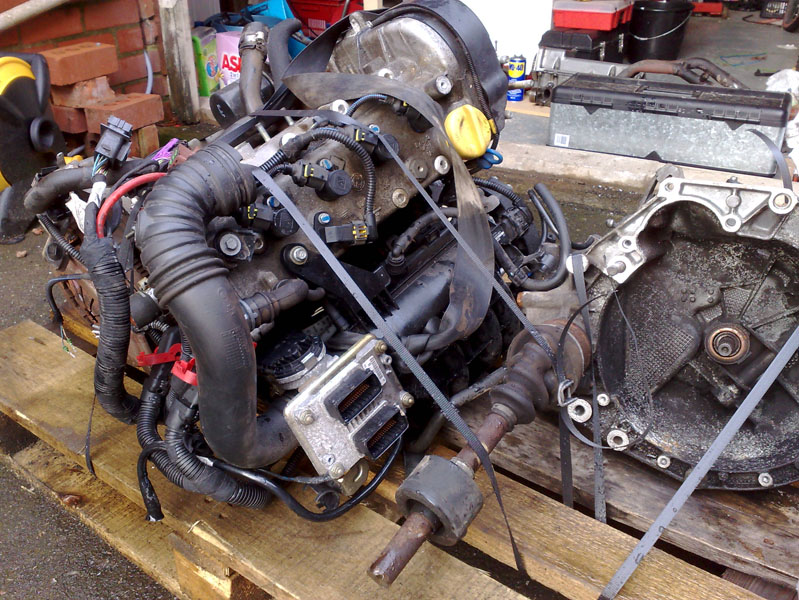

Quick look on ebay and got this from a 2004 Stilo 1.4 16v for £275

dropped it into the car

looked at how close it was and made that sound mechanics make when something looks bad

but it did fit, so that was ok

had the flywheel taken down to 4.7kg

yes.. i know i should've done that before fitting the engine.. but it wasnt ready in time

Wiring and fuel wise my car was setup to run an 8v MPI engine, using wasted spark. The Stilo engine used Coil On Plug, which my ECU can drive if i modified it - but it offers no real world advantage. I fitted a coil pack bracket and matching coils from a MK1 Punto Sporting 1242 16v;

I also fitted the Punto's inlet manifold and throttle body, as the stilo setup was fly by wire and too big to fit in the engine bay.

On the (mk1) 8v engines, the IAT and MAP sensors are seperate units. On the 16v, they are not - so a spot of re-wiring was needed;

one of the problems was that the TDC sensor is in a different location. On the cento, from the crank it goes;

"cam belt | aux belt | TDC trigger ring" This is because its a bit tight with the engine mount. On the 16v's it goes "cam belt| TDC Trigger ring | aux belt". This means if you use the cento alternator and pulley, the TDC sensor is looking at the aux belt, not the teeth. But if you use the 16v alterantor and pulley then the belt fouls the engine mount.

Options are, grind away some of the mount or move the TDC sensor.

Now i know how finicky TDC sensors are and the nightmere it can cause if they're not bob on.. so i chose to leave it alone and attack the mount. Shame the mount was stuck in the car...

sorted!

So yeah, that is how the car stands at the moment. Waiting on delivery of a Supersprint manifold at the moment, will tidy up the wiring and conenct the fuel up sometime this week hopefully.

arc said:Driving back from Bolton today, im watching the temperature gauges. Oil is cooler than usual, around 50c, and water temperature wasnt registering. Odd. So i turned the heaters off and let the engine have some heat back, oil temp begins to climb, water temp starts to register, hits around 70 and then drops off again. How very odd. Hit a slight hill on the motorway and then it starts loosing power, as my speed and revs are dropping, water temp is climbing. GREAT. i know what that means.. engine off and abrupt stop on the hard shoulder, heaters on, rad fan override on, pop the bonnet, but before i do i see the temp still rising, it peaked arond 120c and then sat there.

Looked under the bonnet and there is waterhose off. Had the car not lost power i'd happily convince myself that it was just a pipe coming off leading to a slight overheat, but it didnt play out that way. I walked to the services i'd just past, bought 4.5l of Buxton Spring water and walked back to the car. It had cooled down by now. Filled her. Reattached the hose. Left the expansion cap off and fired her up! ROUGH AS... with bubbles and exhaust fumes coming out the expansion tank.

So that came out;

looks odd this high off the ground

Quick look on ebay and got this from a 2004 Stilo 1.4 16v for £275

dropped it into the car

looked at how close it was and made that sound mechanics make when something looks bad

but it did fit, so that was ok

had the flywheel taken down to 4.7kg

yes.. i know i should've done that before fitting the engine.. but it wasnt ready in time

Wiring and fuel wise my car was setup to run an 8v MPI engine, using wasted spark. The Stilo engine used Coil On Plug, which my ECU can drive if i modified it - but it offers no real world advantage. I fitted a coil pack bracket and matching coils from a MK1 Punto Sporting 1242 16v;

I also fitted the Punto's inlet manifold and throttle body, as the stilo setup was fly by wire and too big to fit in the engine bay.

On the (mk1) 8v engines, the IAT and MAP sensors are seperate units. On the 16v, they are not - so a spot of re-wiring was needed;

one of the problems was that the TDC sensor is in a different location. On the cento, from the crank it goes;

"cam belt | aux belt | TDC trigger ring" This is because its a bit tight with the engine mount. On the 16v's it goes "cam belt| TDC Trigger ring | aux belt". This means if you use the cento alternator and pulley, the TDC sensor is looking at the aux belt, not the teeth. But if you use the 16v alterantor and pulley then the belt fouls the engine mount.

Options are, grind away some of the mount or move the TDC sensor.

Now i know how finicky TDC sensors are and the nightmere it can cause if they're not bob on.. so i chose to leave it alone and attack the mount. Shame the mount was stuck in the car...

sorted!

So yeah, that is how the car stands at the moment. Waiting on delivery of a Supersprint manifold at the moment, will tidy up the wiring and conenct the fuel up sometime this week hopefully.