Finally got to spend a day on the brava, after the marea diesel was taking up last weekend.

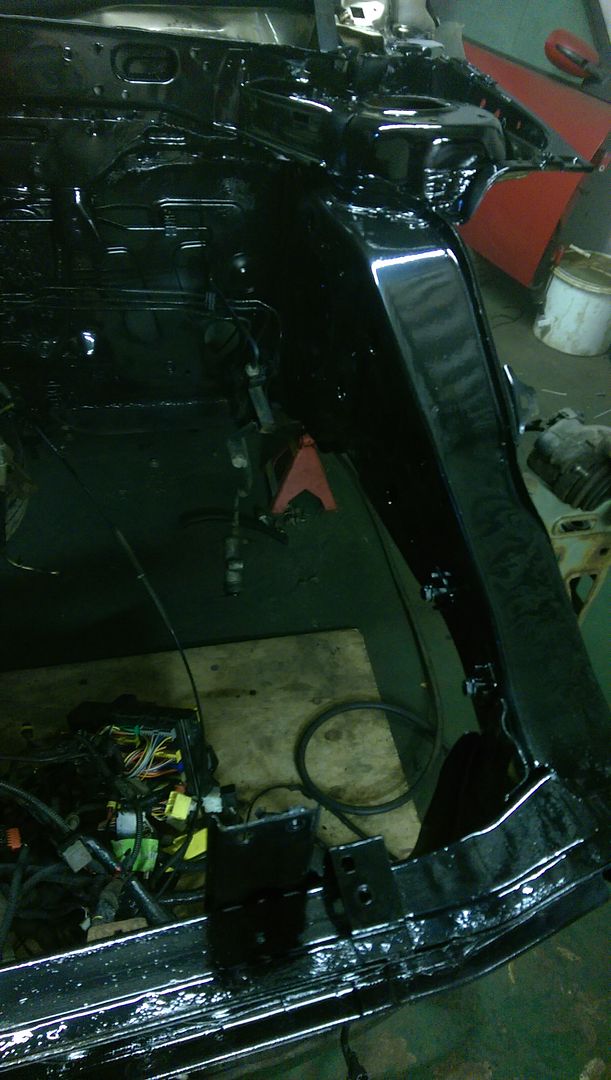

Cleaned up the chassis legs and gave them a coat or two of primer

Then after spending the day at cadwell park on Saturday watching the time attack cars and even a black coupe on track, I've decided I need some track action.

I'd already stripped the engine bay side of the firewall of the sound deadening material, so with gusto I removed the dashboard support bar and set about ripping out all the sound deadening material from the inside of the firewall.

15.5kg removed there plus 2kg from the front side. I then attacked the drivers footwell and got that chipped off too. Another kilo there.

Then I tried the coupe dash support bar and dash but that's a no go.

So put the brava dash support bar back in and refitted the dash loom and fuse box, next was fitting the coupe throttle pedal as I'd heard it was different, but it was identical figment wise.

Next in was the brava bonnet cable back in.

I then spent a very uncomfortable hour and a half trying to remove the coupe fuel lines and tank. The coupe rear tank to bumper panel was refusing to come off, then the off side rear tank trap bolt sheared.

And smart arse here putting the coupe right in the corner of the workshop to save space really didn't help with access.

Still I got the fuel pipes I needed.

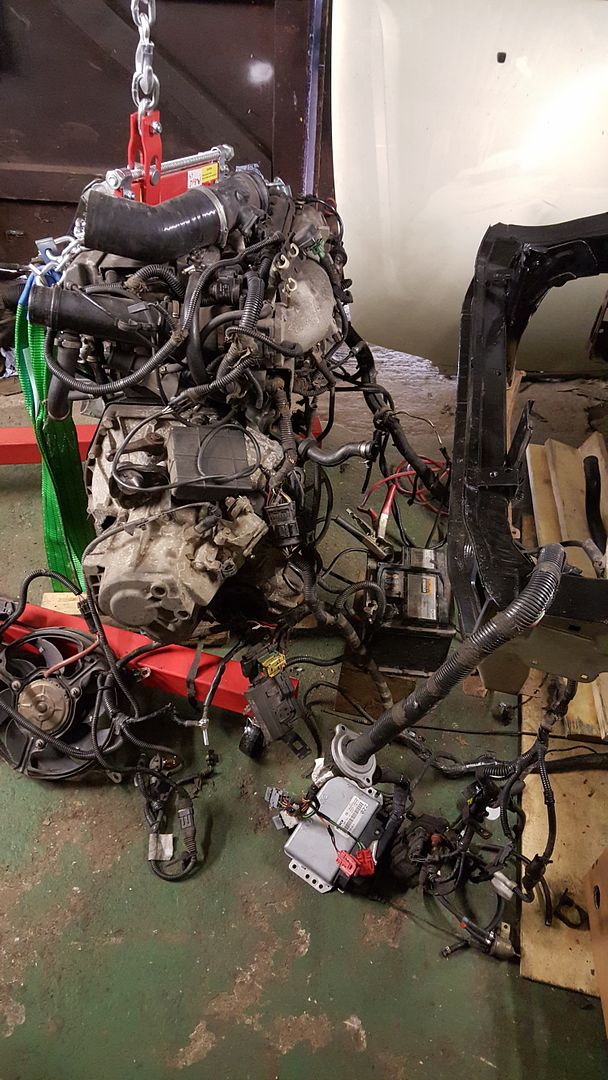

i was going to knock up a cradle to try and get the engine running out of the car, but thinking about all the extra bits I'd have to weld on to mount stuff like the oil cooler on, and plus there's exhaust and cooling to think about, I may as well save myself a shed load of time and just drop the engine in the car now I've got. Decent crane.

So next weeks jobs are to

Fit the coupe loom into the brava

Change the clutch on the coupe engine using the helix kit

Change a couple of weeping gaskets here and there.

Fit the new heater matrix in the heater unit and refit that using the coupe hoses

Then it's time to trial fit the engine and box.