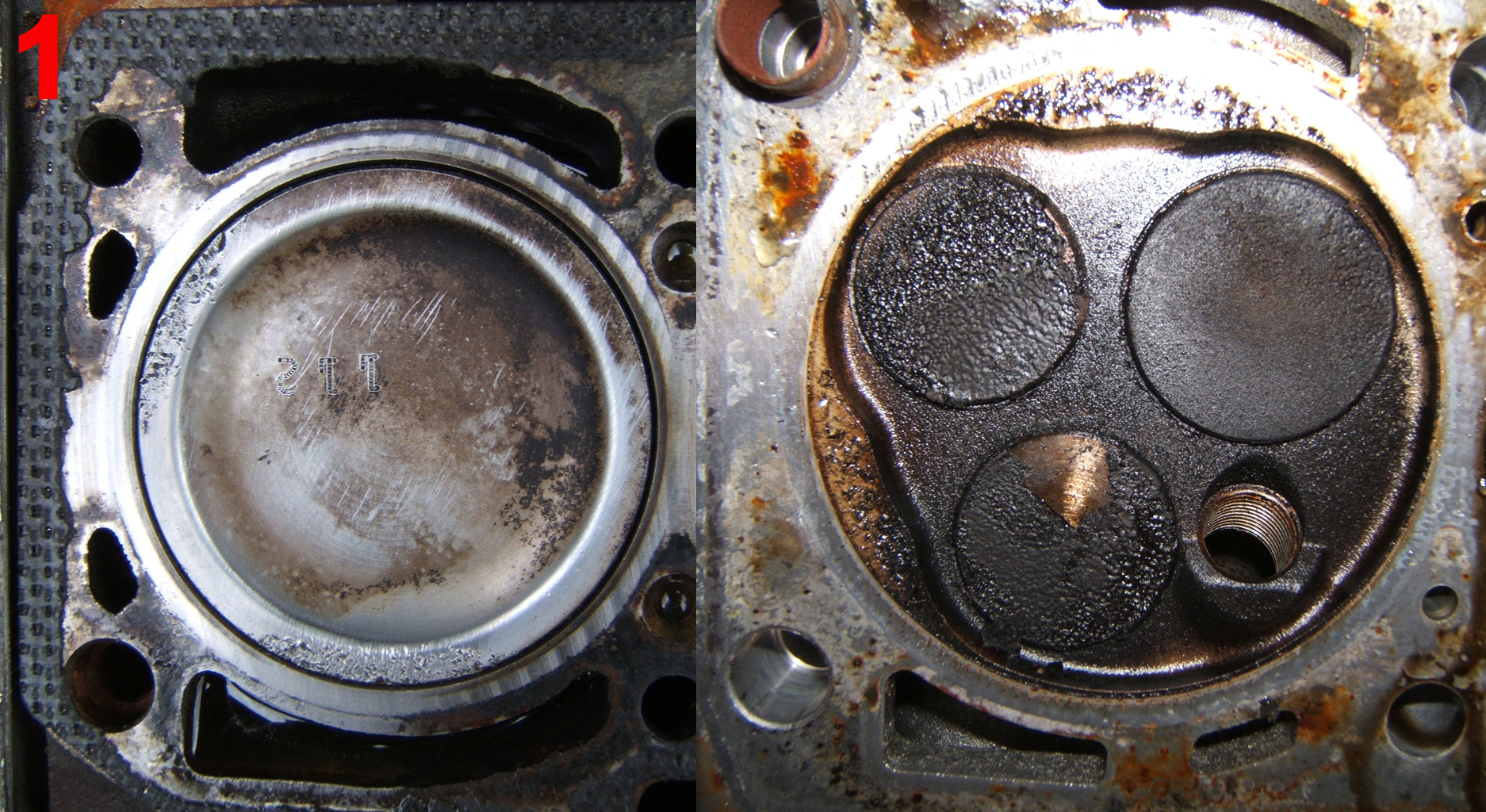

I was getting lots of blue smoke out of the exhaust and my car destroyed two spark plugs in cylinder 2, creating a misfire. So ive decided to repair the car myself. I was getting blue smoke from cold and it would burn off after say 5miles, then sometimes you would get a puff of blue smoke on acceleration. I noticed oil being pushed through the oil breather into the SPI. Rocker cover was leaking oil uniformly all the way round.

Car Started misfiring.

Last week the plug in number 2 was naff.

Had a look at the plugs today and;

Today;

1-oily

2-oily

3-dry light brown

4-dry light brown

Last Week;

1-dry light brown

2-oily (and Broken)

3-dry light brown

4-dry light brown

Also you can smell exhaust under the oil cap.

compression test results, from cold with throttle fully open and dry (though some cylinders must be wet from the oil leak) I didn’t do a wet test.

1 153 psi

2 190

3 190

4 170

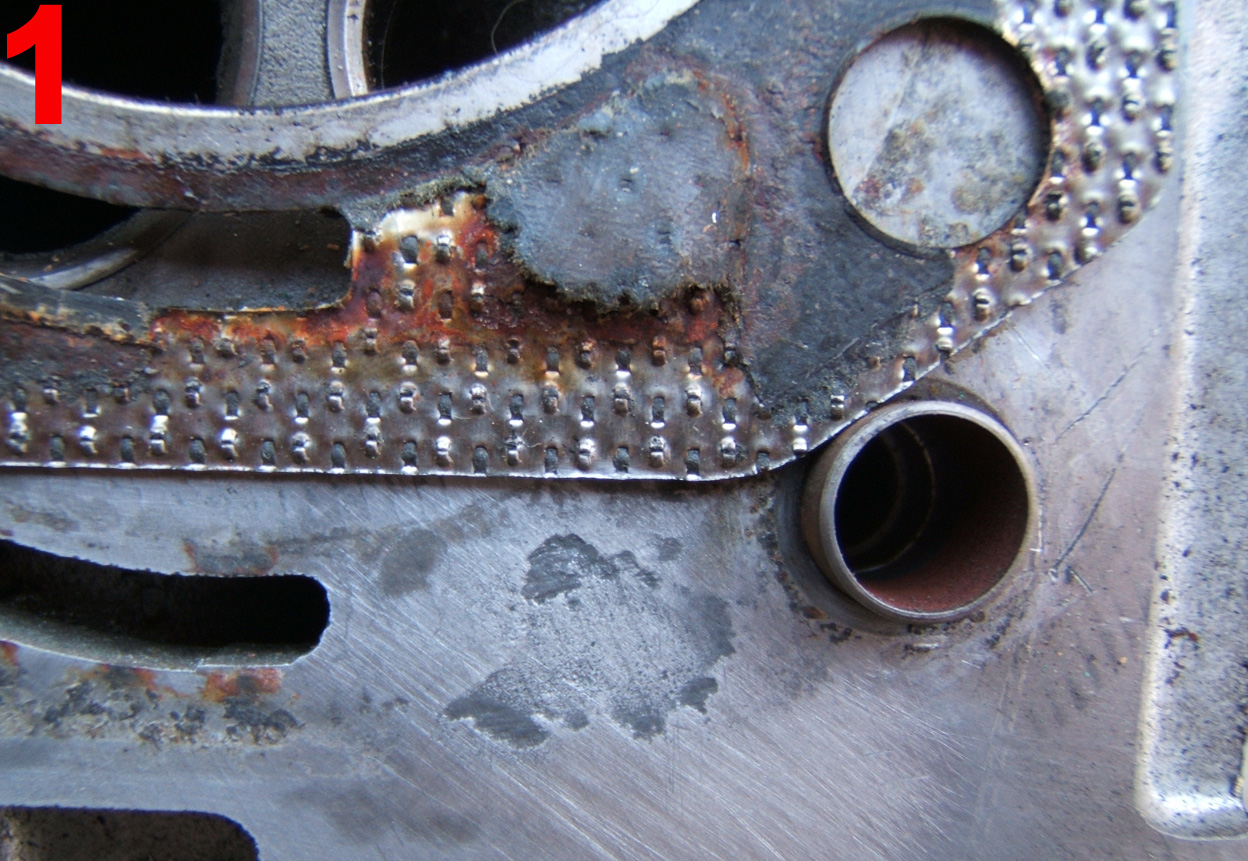

Not got the head of just yet. As expected im struggling with the exhaust manifold.

The rusted nuts have taken six of the eight studs out, probably would have been better if the other two studs came with it.

Taking the down pipe bracket off and the bolt sheared, not surprising really it is a rusted mess.

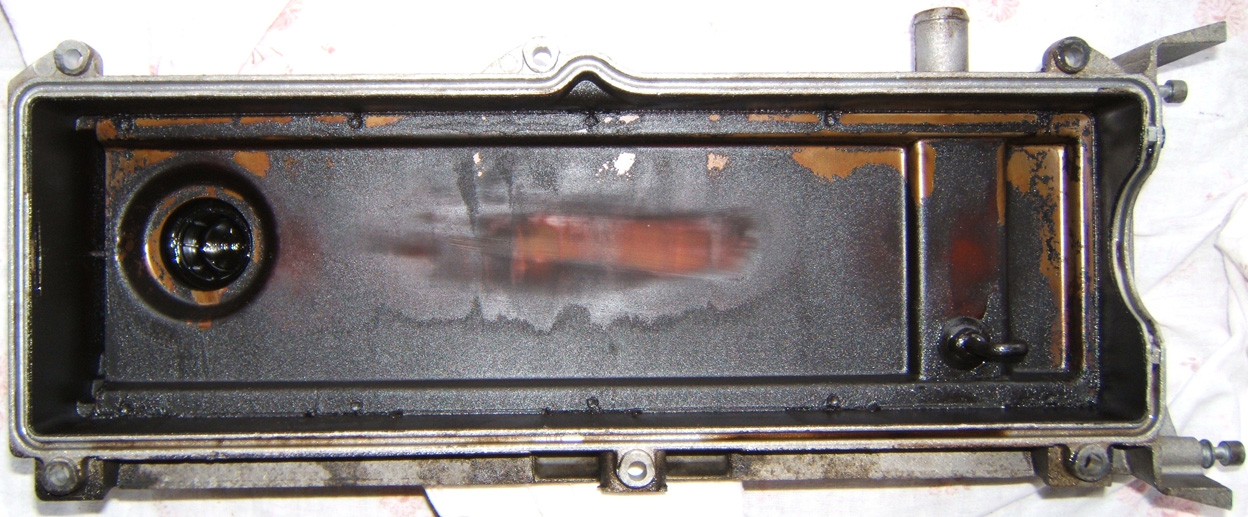

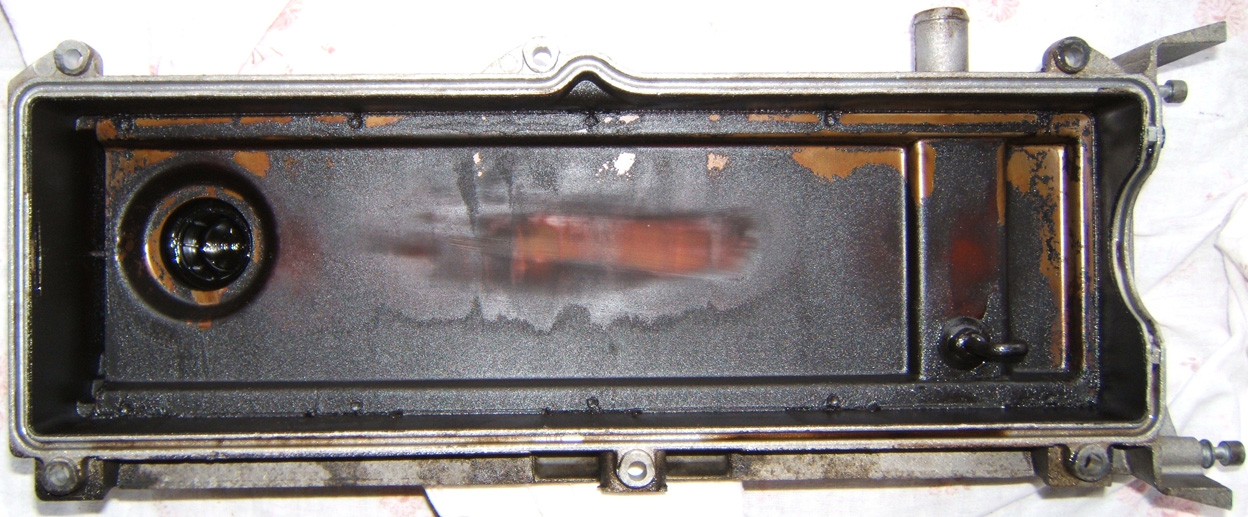

Everything under the rocker cover looks really good though. There was a very strong smell of exhaust under the rocker cover.

When I drained the water there was a very small amount of oil in the water but no water evident in the oil.

I took the air intake manifold of and the branch leading to cylinder-2 had oil.

look at all this (exhaust carbon presumably) on the inside of my rocker cover.

What do you make of this muck on my rocker cover? Im planning to unbolt my exhaust in front of the CAT and take it off in one part, any thoughts?

Car Started misfiring.

Last week the plug in number 2 was naff.

Had a look at the plugs today and;

Today;

1-oily

2-oily

3-dry light brown

4-dry light brown

Last Week;

1-dry light brown

2-oily (and Broken)

3-dry light brown

4-dry light brown

Also you can smell exhaust under the oil cap.

compression test results, from cold with throttle fully open and dry (though some cylinders must be wet from the oil leak) I didn’t do a wet test.

1 153 psi

2 190

3 190

4 170

Not got the head of just yet. As expected im struggling with the exhaust manifold.

The rusted nuts have taken six of the eight studs out, probably would have been better if the other two studs came with it.

Taking the down pipe bracket off and the bolt sheared, not surprising really it is a rusted mess.

Everything under the rocker cover looks really good though. There was a very strong smell of exhaust under the rocker cover.

When I drained the water there was a very small amount of oil in the water but no water evident in the oil.

I took the air intake manifold of and the branch leading to cylinder-2 had oil.

look at all this (exhaust carbon presumably) on the inside of my rocker cover.

What do you make of this muck on my rocker cover? Im planning to unbolt my exhaust in front of the CAT and take it off in one part, any thoughts?

Last edited: