I have been chasing a cold start problem which became a non-start problem.

Having eliminated everything that it could be, including "playing" with a different carb, I decided to replace the original 26IMB after giving it a stripdown and "clean". I inserted the apostrophes because it defininitely wasn't dirty.

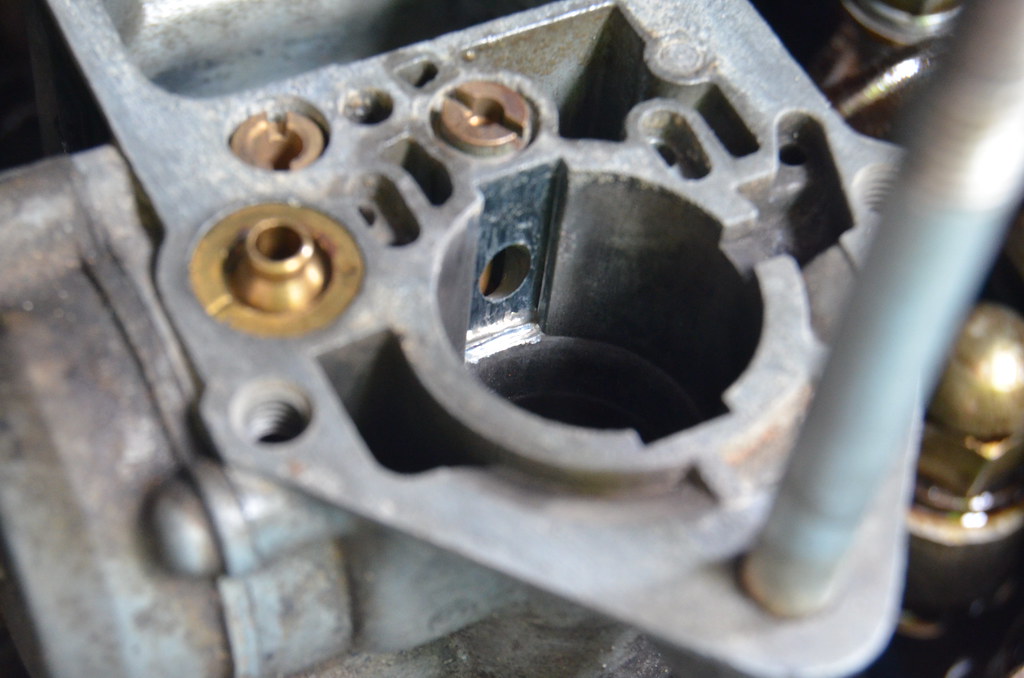

I am familiar with the stripdown and usually find that the auxilliary venturi (the tube with "wings" that fits in the throat of the carb) is a very tight fit and needs gently tappng out. In this case it simply fell out and there is some wiggle in its fit which amounts to about 0.07mm at the most...ie a tiny amount, but noticeable. The interference fit seems likely to be something this device relies on for efficient running. My solution was to insert several carefully trimmed layers of aluminium foil between the blank side and the slot in the body until I got a close fit. When the foil fails and then enters the engine I am hoping it will vaporise quite easily. I noted that on the 28IMB there appears to be a sprung steel device to keep this item from rocking about. .

It's pretty certain that both the carb body and the sliding venturi are worn and so a new carb will be the only long-term solution to this

Has anyone else had this issue and got a solution to it.

Might it affect cold-starting....my original problem?

Having eliminated everything that it could be, including "playing" with a different carb, I decided to replace the original 26IMB after giving it a stripdown and "clean". I inserted the apostrophes because it defininitely wasn't dirty.

I am familiar with the stripdown and usually find that the auxilliary venturi (the tube with "wings" that fits in the throat of the carb) is a very tight fit and needs gently tappng out. In this case it simply fell out and there is some wiggle in its fit which amounts to about 0.07mm at the most...ie a tiny amount, but noticeable. The interference fit seems likely to be something this device relies on for efficient running. My solution was to insert several carefully trimmed layers of aluminium foil between the blank side and the slot in the body until I got a close fit. When the foil fails and then enters the engine I am hoping it will vaporise quite easily. I noted that on the 28IMB there appears to be a sprung steel device to keep this item from rocking about. .

It's pretty certain that both the carb body and the sliding venturi are worn and so a new carb will be the only long-term solution to this

Has anyone else had this issue and got a solution to it.

Might it affect cold-starting....my original problem?