I'm sure I won't be disappointed with the 123 but now I wonder if I was a bit hasty as I could have picked up a used distributor fairly cheaply.

I'm waiting for delivery of a thread repair kit so that I can complete this project. Unfortunately it appears that I have fallen for one of those Ebay sellers who states they are in the UK but actually deliver from China.

I was derusting some smaller pieces such as the engine lifting brackets, so I dumped the old exhaust elbows in the acid. I know these things can be bought cheaply but they are originals and look pretty good now in bare metal. Now I'll have to splash out on some high-temperature paint.:bang:

I need to reassemble the dynamo,to put the cowling back together and fit the exhaust and then I can get the thing going. with spark plugs fitted it certainly has good compression so I think it's going to be a good'un.

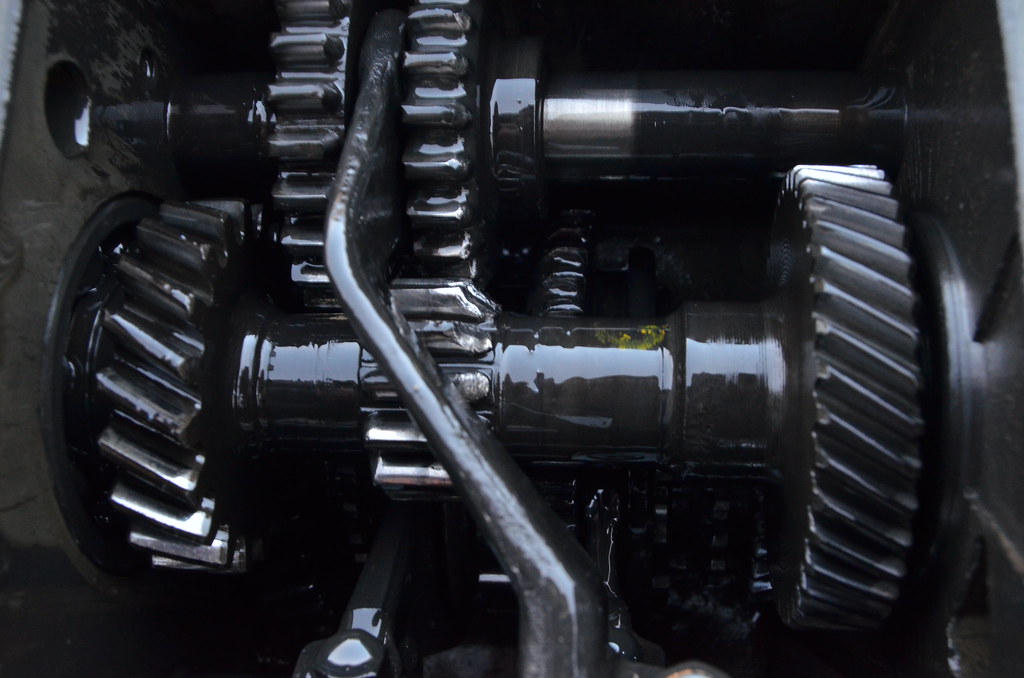

MAL_2200 by Peter Thompson, on Flickr

MAL_2200 by Peter Thompson, on Flickr

I'm waiting for delivery of a thread repair kit so that I can complete this project. Unfortunately it appears that I have fallen for one of those Ebay sellers who states they are in the UK but actually deliver from China.

I was derusting some smaller pieces such as the engine lifting brackets, so I dumped the old exhaust elbows in the acid. I know these things can be bought cheaply but they are originals and look pretty good now in bare metal. Now I'll have to splash out on some high-temperature paint.:bang:

I need to reassemble the dynamo,to put the cowling back together and fit the exhaust and then I can get the thing going. with spark plugs fitted it certainly has good compression so I think it's going to be a good'un.

MAL_2200 by Peter Thompson, on Flickr

MAL_2200 by Peter Thompson, on Flickr