That's a good explanation about the bearings. So it needn't bother me that I got the cheapos.

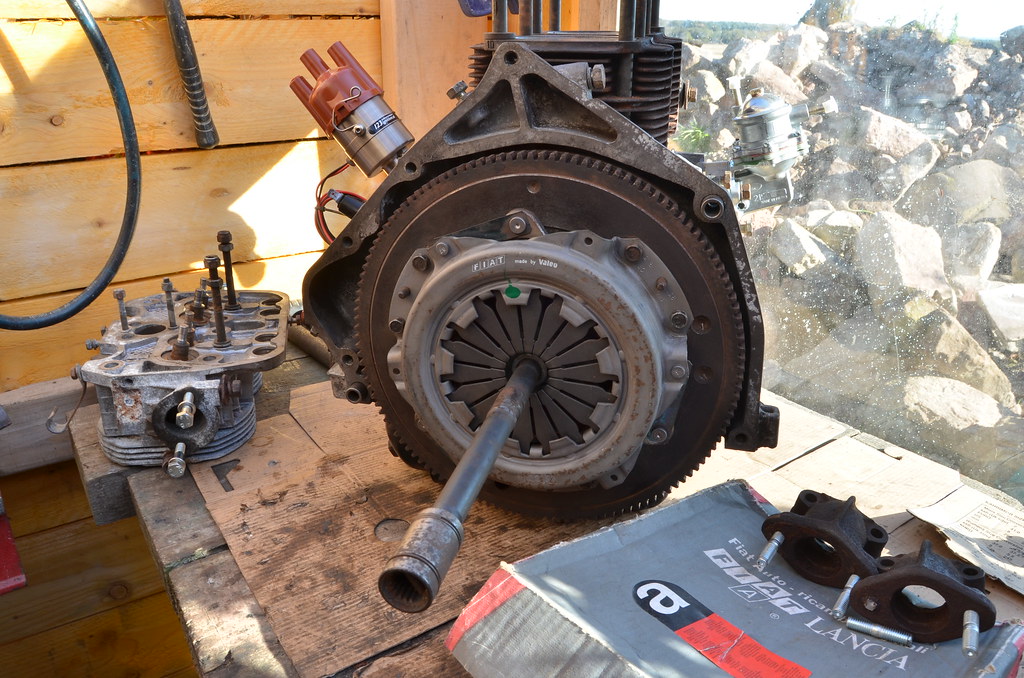

I've been coating everything with the SAE 40 I have left over from my old side-valve; quite thick and sticky but I did plan to do that with the oil pump or to pour oil down the passage where there's an internal hex-screw in the oil-pump casing.

When I built the 500 I was doing it in winter under Sheila's nose in the lovely warm kitchen/dining-room. So on balance I decided it was unsafe to introduce any lubricant other than WD40.

Before I started the engine, having filled the sump, it got loads of revs by hand, then on the starter without the plugs and no petrol and then with all the usual huccups before it actually fired I am sure it was well-oiled.

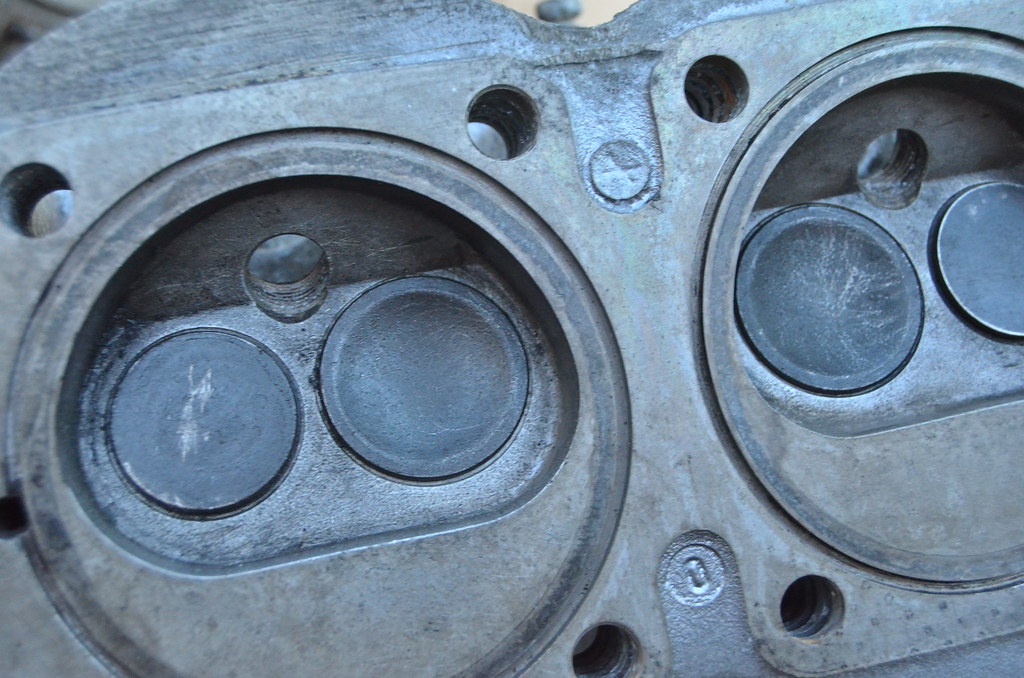

This engine is only very lightly worn and it shows because, without being stiff or crunchy in any way, with new mains and conrod bearings and new piston-rings, but the camshaft not connected, it already has a lot of internal inertia. The cam is new as are the followers, so this thing is going to need careful running-in.

I've been coating everything with the SAE 40 I have left over from my old side-valve; quite thick and sticky but I did plan to do that with the oil pump or to pour oil down the passage where there's an internal hex-screw in the oil-pump casing.

When I built the 500 I was doing it in winter under Sheila's nose in the lovely warm kitchen/dining-room. So on balance I decided it was unsafe to introduce any lubricant other than WD40.

Before I started the engine, having filled the sump, it got loads of revs by hand, then on the starter without the plugs and no petrol and then with all the usual huccups before it actually fired I am sure it was well-oiled.

This engine is only very lightly worn and it shows because, without being stiff or crunchy in any way, with new mains and conrod bearings and new piston-rings, but the camshaft not connected, it already has a lot of internal inertia. The cam is new as are the followers, so this thing is going to need careful running-in.