nzbobc

New member

A search of the forum doesn't yield anything so:

I'm replacing the rear wheel bearings (500F with 126 brakes). Any suggestions on how to remove the outer races?

Haynes says to drift them out with a large tube. It may take me forever to run around and find a tube close to the diameter of the races.

Logically, it would make sense to replace the outer races when replacing the bearings (new ones came with the bearings) in case there's uneven wear, etc. Have you replaced yours or do leave the old races in place?

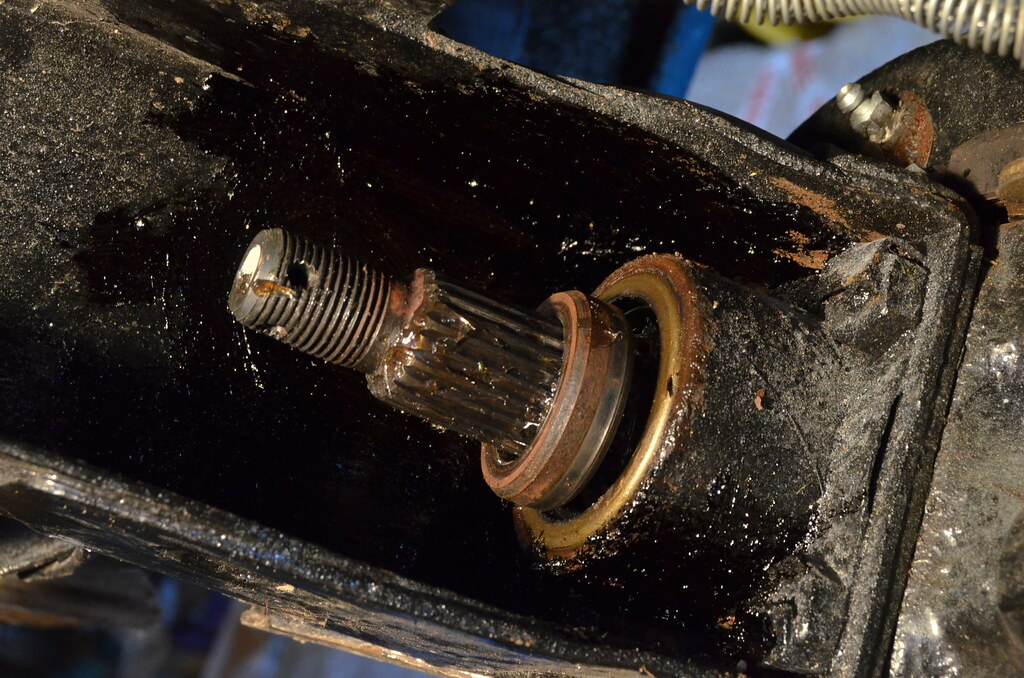

Here's a couple of photos of the races on both sides of the housing and of the bearing I just pulled.

Cheers,

-bob

I'm replacing the rear wheel bearings (500F with 126 brakes). Any suggestions on how to remove the outer races?

Haynes says to drift them out with a large tube. It may take me forever to run around and find a tube close to the diameter of the races.

Logically, it would make sense to replace the outer races when replacing the bearings (new ones came with the bearings) in case there's uneven wear, etc. Have you replaced yours or do leave the old races in place?

Here's a couple of photos of the races on both sides of the housing and of the bearing I just pulled.

Cheers,

-bob