Well done Sean, and thanks for proving that it works

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

General Franko the 1971 500L

- Thread starter Franko500

- Start date

Currently reading:

General Franko the 1971 500L

It's one my Dad made about 20 years ago. Still going strong. Has a battery inside and therefore can be used with LED or buzzer.

The gearbox is back together!

One of the gearboxes out of the 3 Fiat 126 models I got my hands on had a good 1st gear, primary & reverse idler gear. I did order a new one from axel but it has been on back order forever. So I have decided to use a 2nd hand one which appeared to be in good condition.

I was tempted to get the gearbox vapour blasted, but this one came up rather clean and couldn't really justify the extra expense. Maybe I will get the 500D done when I come to build that one.

There is not much to these gearboxes, but they are fiddly things and not a lot of room to work in. After a few trial and errors I got it all in. There is a correct order to build it. Main shaft front bearing and retainer, then the 1st, 3rd & 4th gear hubs, then main shaft and rear bearing. Next is the selector arms, then the primary gear has to be fed in and then fit the bearings.

Then the 2nd gear goes on with the selector arm and rod. This is the fiddly part as the synchro hub has a tendency to fall apart. Insert the ball bearing in the main shaft then fit the speedo drive & nut.

Then insert the special pins in the hole before fitting the other selector rods. Then finally the bearings & springs in the side holes for the selector shafts. Twice the 1st gear came off its hub,

and it is a right bugger to get back on without removing the whole lot. Once done, engage 2nd & 4th gear to lock the box up whilst torqueing the 2 nuts up. Then disengage the gears and fit the selector shaft bolts.

and it is a right bugger to get back on without removing the whole lot. Once done, engage 2nd & 4th gear to lock the box up whilst torqueing the 2 nuts up. Then disengage the gears and fit the selector shaft bolts.

I then fitted the 500 driveshafts to the diff. I found the easiest was to fit the diff back in was to place the bell housing on the bench, lay the diff inside and then fit the box on top. That's when I realised I forgot to fit the main drive shaft from the clutch to the gearbox, so I had to remove the box, fit the shaft and put it back together again.

Then its just a case of fitting the side covers with new gaiters, then fit the new front seal, clutch release arm & bearing. And finally the front cover and selector arm with a new seal. And last but not least the top cover and gearbox mounts.

So now my engine & gearbox are all ready, and I have spent the rest of the day boxing up all my engine and gearbox parts that have been spread around in the garage for the last few weeks and store them away. Finally an end to all this horrible grease and oil mess.

Soon be time to start back on the body -ahhh bodywork

One of the gearboxes out of the 3 Fiat 126 models I got my hands on had a good 1st gear, primary & reverse idler gear. I did order a new one from axel but it has been on back order forever. So I have decided to use a 2nd hand one which appeared to be in good condition.

I was tempted to get the gearbox vapour blasted, but this one came up rather clean and couldn't really justify the extra expense. Maybe I will get the 500D done when I come to build that one.

There is not much to these gearboxes, but they are fiddly things and not a lot of room to work in. After a few trial and errors I got it all in. There is a correct order to build it. Main shaft front bearing and retainer, then the 1st, 3rd & 4th gear hubs, then main shaft and rear bearing. Next is the selector arms, then the primary gear has to be fed in and then fit the bearings.

Then the 2nd gear goes on with the selector arm and rod. This is the fiddly part as the synchro hub has a tendency to fall apart. Insert the ball bearing in the main shaft then fit the speedo drive & nut.

Then insert the special pins in the hole before fitting the other selector rods. Then finally the bearings & springs in the side holes for the selector shafts. Twice the 1st gear came off its hub,

I then fitted the 500 driveshafts to the diff. I found the easiest was to fit the diff back in was to place the bell housing on the bench, lay the diff inside and then fit the box on top. That's when I realised I forgot to fit the main drive shaft from the clutch to the gearbox, so I had to remove the box, fit the shaft and put it back together again.

Then its just a case of fitting the side covers with new gaiters, then fit the new front seal, clutch release arm & bearing. And finally the front cover and selector arm with a new seal. And last but not least the top cover and gearbox mounts.

So now my engine & gearbox are all ready, and I have spent the rest of the day boxing up all my engine and gearbox parts that have been spread around in the garage for the last few weeks and store them away. Finally an end to all this horrible grease and oil mess.

Soon be time to start back on the body -ahhh bodywork

Attachments

-

IMG_9631.JPG1.3 MB · Views: 24

IMG_9631.JPG1.3 MB · Views: 24 -

IMG_9629.JPG1.3 MB · Views: 22

IMG_9629.JPG1.3 MB · Views: 22 -

IMG_9628.JPG1.3 MB · Views: 27

IMG_9628.JPG1.3 MB · Views: 27 -

IMG_9627.JPG1.3 MB · Views: 26

IMG_9627.JPG1.3 MB · Views: 26 -

IMG_9626.JPG1.3 MB · Views: 19

IMG_9626.JPG1.3 MB · Views: 19 -

IMG_9645.JPG1.6 MB · Views: 21

IMG_9645.JPG1.6 MB · Views: 21 -

IMG_9642.JPG1.2 MB · Views: 19

IMG_9642.JPG1.2 MB · Views: 19 -

IMG_9640.JPG1.2 MB · Views: 20

IMG_9640.JPG1.2 MB · Views: 20 -

IMG_9632.JPG1.2 MB · Views: 18

IMG_9632.JPG1.2 MB · Views: 18 -

IMG_9639.JPG1.3 MB · Views: 19

IMG_9639.JPG1.3 MB · Views: 19

You make it all sound so easy.

It looks like one of those professionally reconditioned ones you see on the internet..I dare say much better though.

I got so sick of seeing all my Austin bits all over the place that I started giving them a wipe and putting them on Ebay; I have to get the money to pay for Car Number Two anyway.

The trouble is that I am going to end up blowing it all (hundreds of quids) on oily Fiat parts.:bang:

It looks like one of those professionally reconditioned ones you see on the internet..I dare say much better though.

I got so sick of seeing all my Austin bits all over the place that I started giving them a wipe and putting them on Ebay; I have to get the money to pay for Car Number Two anyway.

The trouble is that I am going to end up blowing it all (hundreds of quids) on oily Fiat parts.:bang:

Ah but think of all the fun you will have on those cold winter days, locked up in your garage with a mig welder!

Yes it does work. It is usually very difficult to select as you have to overcome the sprung loaded bearings that hold the selector rods in place. Its probably easier on a synchro box than a 500 one to engage the gears without it turning though.

I usually will need to give it a good hard shove though. Remember you have a lot more leverage with the gear lever, hence the longer the leaver the easier it is.

Picking another one up during the week. Couldnt resist a bargain and nice to have a spare...

I usually will need to give it a good hard shove though. Remember you have a lot more leverage with the gear lever, hence the longer the leaver the easier it is.

Picking another one up during the week. Couldnt resist a bargain and nice to have a spare...

Sean, when you had your car's bodywork stripped down and the rear wings cut out and before you started to weld in all those pieces that connect the inner sills at the rear, how did you stop the car folding or what did you do to stop the shell twisting or sagging?

This heap I bought would need all those bits replacing and although the door sits nicely in the frame it does sag where the A post is sitting in thin air.

I am just wondering how I would keep the rear suspension mountings at the correct height and aligmment.

If I was mad enough to really jack it up I suspect that the floor under the seats would fold. You can see it start to move upwards.

This heap I bought would need all those bits replacing and although the door sits nicely in the frame it does sag where the A post is sitting in thin air.

I am just wondering how I would keep the rear suspension mountings at the correct height and aligmment.

If I was mad enough to really jack it up I suspect that the floor under the seats would fold. You can see it start to move upwards.

It's sounds like it's too far gone to use itself as reference. I've not personally done this but I've seen friends build an external frame from dimensions and then rebuild bodywork within, using the frame as a reference point.

You could do the same as you have a template car sitting nearby on which to build a frame around. Then it's just a matter of measuring and noting angles for the reference points.

cheers, Steve

You could do the same as you have a template car sitting nearby on which to build a frame around. Then it's just a matter of measuring and noting angles for the reference points.

cheers, Steve

I can see your dilemma Peter.

As you don't have a jig to keep it all in place (I am just in the planning stage to build one) you will need to be very logical and careful before going to mad.

First off I would advise you have 4 wheels & tyres the same size and preferably the same tread depth, check pressures are the same.

then on a flat floor area you can check the ride height either side. You may need to chock the body to adjust the height both sides until even.

Removing the engine first is a good idea as it removes a lot of weight from the vehicle that will help the shell from moving.

No depending on what is left of your car, you can in theory remove the inner & outer sill without causing any structural damage to the car. I did this on the ground and as long as you don't jack it up it will not move much.

I removed the outer sill leaving as much of the 1/4 panel in tact until the inner sill was back in. This will keep the rear end and rear floor in position as the rear floor pan is usually thicker metal, it also has reinforcer plates on the area at the front. The inner B pillar is best left in tact as this prevents the rear floor from dropping.

Leave what you have of the floor where it is for now. if it is attached at the front and rear it will help stop the back and front of the car moving and therefore keep the wheel base where it should be.

I started mine very carefully and eventually found with the sills (one side only) removed, I fitted the door back on and nothing had moved. If you really are unsure you can weld a brace or 2 from the A post to the B post, and even cross braces across the door aperture. ie roof to sills.

Just don't jack the car up, work on a flat floor, chock the wheels front and back, and remember measure twice before welding anything in place.

Even with the sills removed and the door hung in its aperture, you will find you can actually change the gaps slightly by pushing/pulling the A post by hand. Just make sure everything is clamped in place and lines up before tacking things in place.

As you don't have a jig to keep it all in place (I am just in the planning stage to build one) you will need to be very logical and careful before going to mad.

First off I would advise you have 4 wheels & tyres the same size and preferably the same tread depth, check pressures are the same.

then on a flat floor area you can check the ride height either side. You may need to chock the body to adjust the height both sides until even.

Removing the engine first is a good idea as it removes a lot of weight from the vehicle that will help the shell from moving.

No depending on what is left of your car, you can in theory remove the inner & outer sill without causing any structural damage to the car. I did this on the ground and as long as you don't jack it up it will not move much.

I removed the outer sill leaving as much of the 1/4 panel in tact until the inner sill was back in. This will keep the rear end and rear floor in position as the rear floor pan is usually thicker metal, it also has reinforcer plates on the area at the front. The inner B pillar is best left in tact as this prevents the rear floor from dropping.

Leave what you have of the floor where it is for now. if it is attached at the front and rear it will help stop the back and front of the car moving and therefore keep the wheel base where it should be.

I started mine very carefully and eventually found with the sills (one side only) removed, I fitted the door back on and nothing had moved. If you really are unsure you can weld a brace or 2 from the A post to the B post, and even cross braces across the door aperture. ie roof to sills.

Just don't jack the car up, work on a flat floor, chock the wheels front and back, and remember measure twice before welding anything in place.

Even with the sills removed and the door hung in its aperture, you will find you can actually change the gaps slightly by pushing/pulling the A post by hand. Just make sure everything is clamped in place and lines up before tacking things in place.

thisisburdett

New member

- Joined

- Nov 13, 2014

- Messages

- 130

- Points

- 43

I can see your dilemma Peter.

As you don't have a jig to keep it all in place (I am just in the planning stage to build one) you will need to be very logical and careful before going to mad.

First off I would advise you have 4 wheels & tyres the same size and preferably the same tread depth, check pressures are the same.

then on a flat floor area you can check the ride height either side. You may need to chock the body to adjust the height both sides until even.

Removing the engine first is a good idea as it removes a lot of weight from the vehicle that will help the shell from moving.

No depending on what is left of your car, you can in theory remove the inner & outer sill without causing any structural damage to the car. I did this on the ground and as long as you don't jack it up it will not move much.

I removed the outer sill leaving as much of the 1/4 panel in tact until the inner sill was back in. This will keep the rear end and rear floor in position as the rear floor pan is usually thicker metal, it also has reinforcer plates on the area at the front. The inner B pillar is best left in tact as this prevents the rear floor from dropping.

Leave what you have of the floor where it is for now. if it is attached at the front and rear it will help stop the back and front of the car moving and therefore keep the wheel base where it should be.

I started mine very carefully and eventually found with the sills (one side only) removed, I fitted the door back on and nothing had moved. If you really are unsure you can weld a brace or 2 from the A post to the B post, and even cross braces across the door aperture. ie roof to sills.

Just don't jack the car up, work on a flat floor, chock the wheels front and back, and remember measure twice before welding anything in place.

Even with the sills removed and the door hung in its aperture, you will find you can actually change the gaps slightly by pushing/pulling the A post by hand. Just make sure everything is clamped in place and lines up before tacking things in place.

Sean, when you had your car's bodywork stripped down and the rear wings cut out and before you started to weld in all those pieces that connect the inner sills at the rear, how did you stop the car folding or what did you do to stop the shell twisting or sagging?

This heap I bought would need all those bits replacing and although the door sits nicely in the frame it does sag where the A post is sitting in thin air.

I am just wondering how I would keep the rear suspension mountings at the correct height and aligmment.

If I was mad enough to really jack it up I suspect that the floor under the seats would fold. You can see it start to move upwards.

He's only gonna bloody do it!!!

I have every faith in you Peter!

go for it!

I started a new job 3 weeks ago so I haven't had too much time for the car.

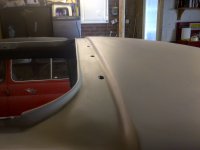

But I have slowly been working on the filler work for the roof section. It didn't take too much work, generally 1 thin spread of filler in places, knock it back with 40 grit to get the general shape right. Then another thin spread and then flat that back with 40, 80 & finish in 120 grit paper.

Then a good clean up and a coat of etch primer.

I have attached a couple of the original roof damage for comparison. I am quite pleased with the result. It always best to put a wet coat of etch over the repair so you can see if the repair looks right when wet, as when it dries you will always see the filler area. The roof is al ready for primer now, so on to some of the other panels.

But I have slowly been working on the filler work for the roof section. It didn't take too much work, generally 1 thin spread of filler in places, knock it back with 40 grit to get the general shape right. Then another thin spread and then flat that back with 40, 80 & finish in 120 grit paper.

Then a good clean up and a coat of etch primer.

I have attached a couple of the original roof damage for comparison. I am quite pleased with the result. It always best to put a wet coat of etch over the repair so you can see if the repair looks right when wet, as when it dries you will always see the filler area. The roof is al ready for primer now, so on to some of the other panels.

Attachments

-

IMG-20150602-00143.jpg395.5 KB · Views: 26

IMG-20150602-00143.jpg395.5 KB · Views: 26 -

IMG-20150602-00124.jpg443.5 KB · Views: 22

IMG-20150602-00124.jpg443.5 KB · Views: 22 -

IMG-20150602-00123.jpg433.2 KB · Views: 23

IMG-20150602-00123.jpg433.2 KB · Views: 23 -

IMG_5365.JPG452.4 KB · Views: 23

IMG_5365.JPG452.4 KB · Views: 23 -

IMG_4023.JPG451.7 KB · Views: 23

IMG_4023.JPG451.7 KB · Views: 23 -

IMG-20150602-00142.jpg358 KB · Views: 22

IMG-20150602-00142.jpg358 KB · Views: 22 -

IMG-20150602-00134.jpg443.7 KB · Views: 22

IMG-20150602-00134.jpg443.7 KB · Views: 22 -

IMG-20150602-00136.jpg343 KB · Views: 21

IMG-20150602-00136.jpg343 KB · Views: 21 -

IMG-20150602-00139.jpg462.6 KB · Views: 20

IMG-20150602-00139.jpg462.6 KB · Views: 20 -

IMG-20150602-00145.jpg437.6 KB · Views: 25

IMG-20150602-00145.jpg437.6 KB · Views: 25 -

IMG-20150602-00141.jpg390.7 KB · Views: 24

IMG-20150602-00141.jpg390.7 KB · Views: 24

Looks really good. I bet the roof channel was a right pain in the derrier to get right with the limited access and contrasting angles.

You have a lot more patience tha me

You have a lot more patience tha me

MarkOz

New member

Brilliant job

Canadian1972

New member

- Joined

- Jun 9, 2015

- Messages

- 16

- Points

- 2

Respect for your work! Love it.