- Joined

- Dec 11, 2011

- Messages

- 16

- Points

- 7

I've rebuilt the carb on my 500L, after only a minor problem with the throttle linkage (I put it on the wrong way round meaning it revved like mad) it all seems to be just about working.

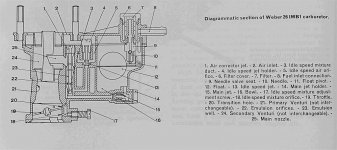

My problem though is trying to set it perfectly - the Haynes manual suggests tightening the needle valve to produce the fastest, smoothest idle. Which I have done and then altered the throttle stop to slow it down a little. The problem is, that the needle valve is as tight as it will go which doesn't seem right to me. I've then played around with both the throttle and needle valve to get a smooth idle without it being so tight, but then I seem to lose power at full throttle (too little fuel I guess).

Anyone got any advice on how to get this tuned correctly? Any hints & tips would be appreciated...

My problem though is trying to set it perfectly - the Haynes manual suggests tightening the needle valve to produce the fastest, smoothest idle. Which I have done and then altered the throttle stop to slow it down a little. The problem is, that the needle valve is as tight as it will go which doesn't seem right to me. I've then played around with both the throttle and needle valve to get a smooth idle without it being so tight, but then I seem to lose power at full throttle (too little fuel I guess).

Anyone got any advice on how to get this tuned correctly? Any hints & tips would be appreciated...