Could someone help me on giving me some detailed instructions on how to set the ignition timing on my 1967 fiat 500F? I have a bulb light with pos and neg cables for testing; just don't know where to attach it and don’t know which spark plug chamber to check to see whether the piston is TDC before adjusting the distributor. Any DETAILED help, I would appreciate it greatly!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

General Help setting ignition timing on Fiat 500 F

- Thread starter gloverbi

- Start date

Currently reading:

General Help setting ignition timing on Fiat 500 F

- Joined

- Apr 4, 2007

- Messages

- 675

- Points

- 168

Hello and welcome to the forum

If you look at the 'sticky' at the top of the classic 500 section theres the thread for the online haynes manual which has a good guide to setting up your timing heres the direct link :

http://members.multimania.nl/dm5675/haynes/Haynes_UK.htm

Any more probs let us know

If you look at the 'sticky' at the top of the classic 500 section theres the thread for the online haynes manual which has a good guide to setting up your timing heres the direct link :

http://members.multimania.nl/dm5675/haynes/Haynes_UK.htm

Any more probs let us know

This is what I do -

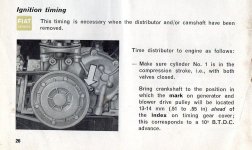

1) All 500s have a timing mark cut into the pulley and when lined up with the arrow on the crankcase, this marks TDC (Photo 1 marked T). The static timing needs to be adjusted so that the points are just about to open to fire cylinder 1 at 10 degrees before TDC.

2) This is achieved by making another mark on the pulley 13mm around the circumference from the static timing mark in a clockwise direction. (Photo 1 marked A) For interest, the pulley has a diameter of 150mm and therefore a circumference of 471.24mm. 10 degrees = 471.24/36 = 13.1mm.

3) Line this new mark up with the arrow on the crankcase and rotate the distributor until the points are just about to open. Photo 2 shows the points about to open and the rotor pointing toward the block. The static timing is now set.

There are a couple of points to note -

Because the pistons move in phase (both up and down together), they will both be at TDC together though only one will be at the top of the compression cycle and the other about to begin the intake cycle.

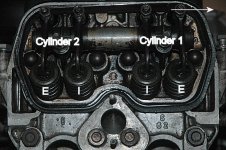

Cylinder 1 is the one closest to the rear of the car and when it is at the top of the compression cycle, the rotor should be pointing toward the engine block. Photo 3 shows the valve gear with the rocker cover removed. The arrow points to the rear of the car (I = intake & E = exhaust).

If you remove the distributor to set the points, leave the worm drive in situ and only remove the distributor and shaft down to the dog. That is, undo the nut that you loosen when you rotate the distributor to set the timing and pull the distributor out from this point up.

The dynamic timing (advance) can be set and checked in the usual way using a timing light when the engine is running.

Hope this helps,

Chris

PS: You can get rid of the points altogether by fitting a '123 ignition'.

1) All 500s have a timing mark cut into the pulley and when lined up with the arrow on the crankcase, this marks TDC (Photo 1 marked T). The static timing needs to be adjusted so that the points are just about to open to fire cylinder 1 at 10 degrees before TDC.

2) This is achieved by making another mark on the pulley 13mm around the circumference from the static timing mark in a clockwise direction. (Photo 1 marked A) For interest, the pulley has a diameter of 150mm and therefore a circumference of 471.24mm. 10 degrees = 471.24/36 = 13.1mm.

3) Line this new mark up with the arrow on the crankcase and rotate the distributor until the points are just about to open. Photo 2 shows the points about to open and the rotor pointing toward the block. The static timing is now set.

There are a couple of points to note -

Because the pistons move in phase (both up and down together), they will both be at TDC together though only one will be at the top of the compression cycle and the other about to begin the intake cycle.

Cylinder 1 is the one closest to the rear of the car and when it is at the top of the compression cycle, the rotor should be pointing toward the engine block. Photo 3 shows the valve gear with the rocker cover removed. The arrow points to the rear of the car (I = intake & E = exhaust).

If you remove the distributor to set the points, leave the worm drive in situ and only remove the distributor and shaft down to the dog. That is, undo the nut that you loosen when you rotate the distributor to set the timing and pull the distributor out from this point up.

The dynamic timing (advance) can be set and checked in the usual way using a timing light when the engine is running.

Hope this helps,

Chris

PS: You can get rid of the points altogether by fitting a '123 ignition'.

Attachments

There has been some discussion lately about distributors, points, timing etc. so I found a thread that I posted a couple of years ago on how to set the static timing using a standard 500 distributor.

Also, I also have a spare distributor which I'll dismantle, photograph and reassemble using a breakerless setup if there is any interest in seeing this done.

Chris

Also, I also have a spare distributor which I'll dismantle, photograph and reassemble using a breakerless setup if there is any interest in seeing this done.

Chris

Jake,

The standard distributor is in two parts - a lower part with a gear drive to the camshaft and an upper part with a dog that fits into the lower part. From memory, the only gasket is between the lower part and the crankcase.

If you remove the entire distributor down to the gear drive make sure you retime the engine correctly. Setting it at TDC and noting the orientation of the parts is a very good start.

Chris

The standard distributor is in two parts - a lower part with a gear drive to the camshaft and an upper part with a dog that fits into the lower part. From memory, the only gasket is between the lower part and the crankcase.

If you remove the entire distributor down to the gear drive make sure you retime the engine correctly. Setting it at TDC and noting the orientation of the parts is a very good start.

Chris

Attachments

jjacob

Member

Gloverbi,

If you can get a timing light, you can set the dynamic (engine running) timing, which is much more accurate than static timing.

As Chris noted, the static timing is 10 degrees before top dead center (BTDC).

The dynamic timing is 18 degrees BTDC.

You need to have the dwell (point gap) set correctly. If you have an electronic ignition then you can bypass this. If not, I highly recommend that you install one. I used the Pertronix system which works great. Points removal should be the first modification anyone does to a 500. Dwell affects timing.

Static advance (10 degrees) is good for getting the timing close enough so the engine will start and run reasonably well. You really need to set the engine up for maximum dynamic advance. This is 18 degrees.

On the pulley locate the TDC mark. Now make another mark 25mm clockwise from that mark. This is 18 degrees BTDC. Loosen the distributor so it can be turned (but not too loose). Install your timing light. Start the engine and rev the engine to at least 3000 rpm. Aim the timing light at the mark on the timing case and turn the distributor until the 18 degree mark you made lines up with the mark on the timing case. Tighten the distributor down and recheck the timing.

John

If you can get a timing light, you can set the dynamic (engine running) timing, which is much more accurate than static timing.

As Chris noted, the static timing is 10 degrees before top dead center (BTDC).

The dynamic timing is 18 degrees BTDC.

You need to have the dwell (point gap) set correctly. If you have an electronic ignition then you can bypass this. If not, I highly recommend that you install one. I used the Pertronix system which works great. Points removal should be the first modification anyone does to a 500. Dwell affects timing.

Static advance (10 degrees) is good for getting the timing close enough so the engine will start and run reasonably well. You really need to set the engine up for maximum dynamic advance. This is 18 degrees.

On the pulley locate the TDC mark. Now make another mark 25mm clockwise from that mark. This is 18 degrees BTDC. Loosen the distributor so it can be turned (but not too loose). Install your timing light. Start the engine and rev the engine to at least 3000 rpm. Aim the timing light at the mark on the timing case and turn the distributor until the 18 degree mark you made lines up with the mark on the timing case. Tighten the distributor down and recheck the timing.

John

Jake,

If you remove the entire distributor down to the gear drive make sure you retime the engine correctly. Setting it at TDC and noting the orientation of the parts is a very good start.

Chris

Chris,

Do you mean with re-timing normal timing process(points,advance etc). I think the distributor should go in to same "grooves" with the cam?

Jake,

The gear drive will re-engage the camshaft easily. What you have to make sure of is that when reinserted, the rotor is pointing in the same direction as it was prior to removal. If not, the distributor shaft will have rotated and the engine will not be able to have the timing set properly. You only have about 20 degrees of rotation of the upper part of the distributor on its base to adjust the timing, so you need to be in that range when you replace the distributor after servicing.

If you are going to remove the distributor entirely, take note of the amount and direction the rotor rotates on removal as well as where it was pointing prior to removal. This will help a lot when you replace it. Once you replace the whole distributor and its new gasket, you will only have to remove the upper part in future - this simplifies things a lot.

I'd invest in a breakerless (Hall effect) ignition module while you are at it as the points/condenser set up are a definite weak point with all Kettering style ignition systems. As John has said, once the initial setup at 10 degrees is complete and the engine is running, adjust the timing by rotating the distributor so that at about 3000rpm you have a maximum advance of 18 degrees. Of course if you replace the whole thing with an electronic device (eg: 123ignition) the advance curve is set for you automatically though even with these, it's still worth doing the timing light thing despite what the companies marketing these devices say.

Good luck and keep us posted,

Chris

The gear drive will re-engage the camshaft easily. What you have to make sure of is that when reinserted, the rotor is pointing in the same direction as it was prior to removal. If not, the distributor shaft will have rotated and the engine will not be able to have the timing set properly. You only have about 20 degrees of rotation of the upper part of the distributor on its base to adjust the timing, so you need to be in that range when you replace the distributor after servicing.

If you are going to remove the distributor entirely, take note of the amount and direction the rotor rotates on removal as well as where it was pointing prior to removal. This will help a lot when you replace it. Once you replace the whole distributor and its new gasket, you will only have to remove the upper part in future - this simplifies things a lot.

I'd invest in a breakerless (Hall effect) ignition module while you are at it as the points/condenser set up are a definite weak point with all Kettering style ignition systems. As John has said, once the initial setup at 10 degrees is complete and the engine is running, adjust the timing by rotating the distributor so that at about 3000rpm you have a maximum advance of 18 degrees. Of course if you replace the whole thing with an electronic device (eg: 123ignition) the advance curve is set for you automatically though even with these, it's still worth doing the timing light thing despite what the companies marketing these devices say.

Good luck and keep us posted,

Chris

124spiderman

Member

Thanks heaps for the info. I've just replaced my old points with a Hot-Spark Electronic Ignition kit as I was getting all sorts of probs due to warped points base etc. (Highly recommend ditching the points/condesor for this set up)

Can you tell me does the 650cc engine (FSM 126) have the same max advance of 18 deg or is it different as I cannot find any specs on this.

Cheers and drive safe

Can you tell me does the 650cc engine (FSM 126) have the same max advance of 18 deg or is it different as I cannot find any specs on this.

Cheers and drive safe

According to my Haynes manual, the 126 has a static advance of 10deg BTDC and a maximum advance of 18deg +/- 2deg BTDC achieved at 3000rpm.

Chris

Chris

124spiderman

Member

Gloverbi,

..........................Start the engine and rev the engine to at least 3000 rpm. Aim the timing light at the mark on the timing case and turn the distributor until the 18 degree mark you made lines up with the mark on the timing case.

John

I'm assuming you mean the TDC (arrow) mark on the timing cover as with 650 motors there are 3 marks

Last edited:

Zebravanman

New member

- Joined

- Aug 17, 2014

- Messages

- 50

- Points

- 19

I just did this on my 500L (with the 650 engine fitted) I've only had it for a hand full of weeks but I did mine with a Sealy strobe light which worked ok I think.

The only problem I had was the simplest thing of all and that was setting the correct gap for the contact breakers, I couldn't achieve the correct gap. The problem I had was there was not enough movement in the adjustment slot to achieve the gap of 0.5mm (mid range within the haynes manual), I had to modify the slotted hole to achieve this, has anyone had a similar experience ?

Anyway, when I achieved the gap checked the timing with the engine idling and the notch in the pulley lined up with the TDC arrow on the casing. As I revved as per the graph in the Haynes manual I checked that the notch moved to the 10 degs point on the housing and this was correct. Alternatively I adjusted the strobe light to 10 Degs on the rotary knob and did the same and the notch on the pulley moved to the TDC arrow, which is also correct. I had a multimeter connected to the No1 HT lead to read REVs.

I then revved the engine to approx 3000 rpm and I set the strobe light to 18 DEGS on the rotary knob as the engine RPM increased the notch on the pulley moved to the TDC arrow and was only slightly off. I rotated the Distributor ever so slightly to align the arrow with the notch on the pulley with the strobe gun set to 18 Degs and 3000 rpm.

The clamp nut on the distributor was tightened, it appears to be running ok.

The only problem I had was the simplest thing of all and that was setting the correct gap for the contact breakers, I couldn't achieve the correct gap. The problem I had was there was not enough movement in the adjustment slot to achieve the gap of 0.5mm (mid range within the haynes manual), I had to modify the slotted hole to achieve this, has anyone had a similar experience ?

Anyway, when I achieved the gap checked the timing with the engine idling and the notch in the pulley lined up with the TDC arrow on the casing. As I revved as per the graph in the Haynes manual I checked that the notch moved to the 10 degs point on the housing and this was correct. Alternatively I adjusted the strobe light to 10 Degs on the rotary knob and did the same and the notch on the pulley moved to the TDC arrow, which is also correct. I had a multimeter connected to the No1 HT lead to read REVs.

I then revved the engine to approx 3000 rpm and I set the strobe light to 18 DEGS on the rotary knob as the engine RPM increased the notch on the pulley moved to the TDC arrow and was only slightly off. I rotated the Distributor ever so slightly to align the arrow with the notch on the pulley with the strobe gun set to 18 Degs and 3000 rpm.

The clamp nut on the distributor was tightened, it appears to be running ok.

124spiderman

Member

,........................................

....................... checked the timing with the engine idling and the notch in the pulley lined up with the TDC arrow on the casing. As I revved as per the graph in the Haynes manual I checked that the notch moved to the 10 degs point on the housing and this was correct. Alternatively I adjusted the strobe light to 10 Degs on the rotary knob and did the same and the notch on the pulley moved to the TDC arrow, which is also correct. I had a multimeter connected to the No1 HT lead to read REVs.

I then revved the engine to approx 3000 rpm and I set the strobe light to 18 DEGS on the rotary knob as the engine RPM increased the notch on the pulley moved to the TDC arrow and was only slightly off. I rotated the Distributor ever so slightly to align the arrow with the notch on the pulley with the strobe gun set to 18 Degs and 3000 rpm.

The clamp nut on the distributor was tightened, it appears to be running ok.

You say at idle the notch in the pulley lined up with the TDC arrow on the casing....that isn't correct because that's at TDC, at idle the mark on the pulley should be 10 DEG Before Top Dead Centre i.e approx. 13mm BEFORE the arrow on cover. You'll find it idles ok, but no grunt as the ignition is retarded. Am I correct anyone?

Last edited:

Zebravanman

New member

- Joined

- Aug 17, 2014

- Messages

- 50

- Points

- 19

You say at idle the notch in the pulley lined up with the TDC arrow on the casing....that isn't correct because that's at TDC, at idle the mark on the pulley should be 10 DEG Before Top Dead Centre i.e approx. 13mm BEFORE the arrow on cover. You'll find it idles ok, but no grunt as the ignition is retarded. Am I correct anyone?

mmmm ok, Im happy to be corrected, like I said I've only just bought it, maybe I'm interpreting the graph incorrectly in the Haynes manual, my interpretation of the graph is 0 degs at 1400rpm and 10 degs by 2200rpm then 18 degs by 3000rpm.

As long as my total timing of 18 Degs is set correctly at 3000rpm I guess I get what I get at tick over anyway.

If anyone could help it would help me as well.

Last edited:

It should 10 degrees BTDC at tick over, so just under 1000 RPM, this will vary slightly with modern fuel, if I remember correctly it needs to be advanced slightly as modern fuels combust slower than old leaded petrol. I find it best to set it at 10 degrees BTDC with a strobe and adjust it slightly either way by ear to find the best response from the engine. My engine is set a couple of degrees advanced, it's where it seems to run best.

Tony

Tony

looigi

New member

Hi Zebravanman,

No, you had it right. By setting 18 deg on your timing light and running the car at 3000RPM, you are setting the correct timing.

Setting 18 deg on the timing light makes the light flash 18 deg early, so the TDC mark on the pulley will line up with the mark on the case if the timing is correctly set. You can do the same check at idle by setting 10 deg on your light, however in my experience it is best to get it right at the higher RPM and live with whatever it turns out to be at idle.

I have a Snap-on light that does the same thing and it makes dynamic timing so very easy on cars with only a TDC mark.

124Spiderman, go and get one of these lights. Honestly, you will never look back!

Chris

No, you had it right. By setting 18 deg on your timing light and running the car at 3000RPM, you are setting the correct timing.

Setting 18 deg on the timing light makes the light flash 18 deg early, so the TDC mark on the pulley will line up with the mark on the case if the timing is correctly set. You can do the same check at idle by setting 10 deg on your light, however in my experience it is best to get it right at the higher RPM and live with whatever it turns out to be at idle.

I have a Snap-on light that does the same thing and it makes dynamic timing so very easy on cars with only a TDC mark.

124Spiderman, go and get one of these lights. Honestly, you will never look back!

Chris

Last edited:

124spiderman

Member

Similar threads

- Replies

- 3

- Views

- 239